SFR2500001500FR500 Vishay, SFR2500001500FR500 Datasheet - Page 8

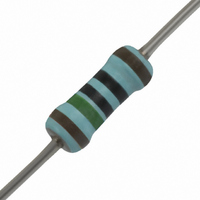

SFR2500001500FR500

Manufacturer Part Number

SFR2500001500FR500

Description

RES 150 OHM METAL FILM .40W 1%

Manufacturer

Vishay

Series

SFR25r

Specifications of SFR2500001500FR500

Temperature Coefficient

±100ppm/°C

Resistance (ohms)

150

Power (watts)

0.4W

Composition

Metal Film

Tolerance

±1%

Size / Dimension

0.098" Dia x 0.295" L (2.50mm x 7.50mm)

Lead Style

Through Hole

Package / Case

Axial

Resistance In Ohms

150

Case

Axial

Resistance

150ohm

Resistance Tolerance

± 1%

Power Rating

400mW

Voltage Rating

250V

Resistor Element Material

Metal Film

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Features

-

Height

-

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

5043ED150R0F12AF5

PPC150YTR

PPC150YTR

TESTS AND REQUIREMENTS

Essentially all tests are carried out in accordance with

IEC 60115-1 specification, category LCT/UCT/56 (rated

temperature range: Lower Category Temperature, Upper

Category temperature; damp heat, steady state, test

duration: 56 days).

The tests are carried out in accordance with IEC 60068-2-xx

test method under standard atmospheric conditions

according to IEC 60068-1, 5.3.

Document Number: 28722

Revision: 06-Aug-10

TEST PROCEDURES AND REQUIREMENTS

IEC

60115-1

CLAUSE

4.16

4.16.2

4.16.3

4.16.4

4.17

4.18

4.19

4.20

4.22

4.23

4.23.2

4.23.3

4.23.4

4.23.5

4.23.6

4.24

METHOD

60068-2-

21 (Ua1)

78 (Cab)

21 (Ub)

21 (Uc)

14 (Na)

30 (Db)

30 (Db)

20 (Tb)

29 (Eb)

20 (Ta)

13 (M)

2 (Ba)

1 (Aa)

TEST

6 (Fc)

IEC

Torsion other half

Climatic sequence:

remaining cycles

Rapid change of

Low air pressure

Robustness of

soldering heat

Resistance to

(steady state)

(accelerated)

(accelerated)

terminations:

Bending half

Solderability

Solderability

(after aging)

temperature

Damp heat

Damp heat

Damp heat

of samples

number of

Tensile all

Vibration

1st cycle

samples

samples

Dry heat

TEST

Bump

Cold

For technical questions, contact:

Standard Metal Film Leaded Resistors

Ø 0.45 mm, load 2.5 N; 4 x 90°

3 x 1500 bumps in 3 directions;

acceleration 10 g; 3 directions;

10 s; 260 °C; 3 mm from body

Ø 0.58 mm, load 5 N; 4 x 90°

for 2 s at 235 °C: Solder bath

for 3 s at 245 °C: Solder bath

Solder bath method; SnPb40

30 min at + 155 °C; 5 cycles

Frequency 10 Hz to 500 Hz;

2 h; 8.5 kPa; 15 °C to 35 °C

Ø 0.58 mm, load 10 N; 10 s

Ø 0.45 mm, load 5 N; 10 s

8 h steam or 16 h 155 °C;

displacement 1.5 mm or

leads immersed 6 mm;

30 min at - 55 °C and

in opposite directions

(SnAgCu0.5) method

(Steps: 0 V to 100 V)

Solder bath method;

loaded with 0.01 P

90 % to 100 % RH

95 % to 100 % RH

90 % to 95 % RH;

total 6 h (3 x 2 h)

Thermal shock:

56 days; 40 °C;

PROCEDURE

5 days; 55 °C;

SnAg3Cu0.5

16 h; 155 °C

24 h; 55 °C;

2 s; 235 °C:

3 s; 245 °C:

2 h; - 55 °C

(SnPb40)

3 x 360°

40 g

70

filmresistorsleaded@vishay.com

In the Test Procedures and Requirements table, tests and

requirements are listed with reference to the relevant clauses

of IEC 60115-1 and IEC 60068-2-xx test methods. A short

description of the test procedure is also given. In some in-

stances deviations from the IEC recommendations were

necessary for our method of specifying. All soldering tests

are performed with mildly activated flux.

RESISTANCE

R ≤ 1 MΩ

R > 1 MΩ

RANGE

ΔR max.: ± (1 % R + 0.05 Ω)

SFR16S

ΔR max.: ± (0.25 % R + 0.05 Ω)

ΔR max.: ± (0.25 % R + 0.05 Ω)

ΔR max.: ± (0.25 % R + 0.05 Ω)

ΔR max.: ± (0.25 % R + 0.05 Ω)

ΔR max.: ± (0.25 % R + 0.05 Ω)

Good tinning (≥ 95 % covered);

Good tinning (≥ 95 % covered);

Vishay BCcomponents

Number of failures < 10 x 10

Number of failures < 10 x 10

ΔR max.: ± (1 % R + 0.05 Ω)

ΔR max.: ± (2 % R + 0.05 Ω)

R

R

REQUIREMENTS

SFR16S/25/25H

ins

ins

No damage

No damage

No damage

no damage

no damage

min.: 1000 MΩ

min.: 1000 MΩ

SFR25

www.vishay.com

± (2 % R

SFR25H

ΔR max.

+ 0.1 Ω)

-6

-6

41