MR106-250-.01% Huntington Electric Inc., MR106-250-.01% Datasheet

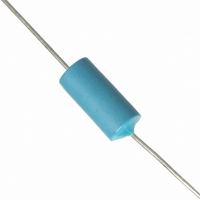

MR106-250-.01%

Specifications of MR106-250-.01%

MR106-250-.01%

Related parts for MR106-250-.01%

MR106-250-.01% Summary of contents

Page 1

... They are based upon an ambient temperature of 125ºC. Ultra-preci- sion wirewound resistors should not be used at a combination of full wattage and maximum ambi- ent temperature where reliability is an important factor. When high reliability is required, a multi- plication factor of 0 ...

Page 2

... Thus the Mills part number MR506Q1K5B calls out an .05 watt resistor of 1.5K , temperature coefficient of 3,900 ppm/ºC, and a tolerance of 0.1%; the part number MR106W5K0B calls out a .25 watt resistor of 5K with the standard TC and a tolerance of ± ...

Page 3

... Page 6 MR100 S ERIES This is our standard line of ultra precision resistors. The sizes below should handle most of your needs; however we can provide other sizes and custom configurations should they be required. Just call the factory and describe your needs MR300 S ERIES These resistors, although dimension- ...

Page 4

... Marking Standard markings are the Mills Resistor logo, part number, tolerance, resistance and date code. On very small resistors the part number may be abbreviated. All markings are made with two part epoxy ink designed to resist most cleaning solvents used during circuit board assembly ...

Page 5

... Mills Resistor’s construction method virtually eliminates this effect. Tolerance and TCR Measurements are made on equipment calibrated to NIST standards. Limitations do exist in measuring two-leaded resistors, so there are minimum practical tolerance limits depending upon the resistance required. The following tables shows these ...