5093NW2R700J08AFX Vishay, 5093NW2R700J08AFX Datasheet

5093NW2R700J08AFX

Specifications of 5093NW2R700J08AFX

232219513278

Related parts for 5093NW2R700J08AFX

5093NW2R700J08AFX Summary of contents

Page 1

... DATA SHEET PR01/02/03 Professional power metal film resistors Product specification Supersedes data of 8th March 2001 File under BCcomponents, BC08 BCcomponents 2001 Jul 13 ...

Page 2

... After a helical groove has been cut in the resistive layer, tinned connecting wires of electrolytic copper or copper-clad iron are welded to the end-caps. The resistors are coated with a red, nonflammable lacquer which provides electrical, mechanical and PR02 PR01 Cu-lead 0 ...

Page 3

... BCcomponents Professional power metal film resistors ORDERING INFORMATION Table 1 Ordering code indicating resistor type and packaging LEAD TOL TYPE RADIAL TAPED mm) (%) 4000 units 1 PR01 Cu 0.6 06 197 5 03... 1 Cu 0.8 5 PR02 5 FeCu 0 0.8 PR03 1 FeCu 0.6 5 Table 2 Ordering code indicating resistor type and packaging ...

Page 4

... The last digit indicates the resistance decade in accordance with Table 3. FUNCTIONAL DESCRIPTION Product characterization Standard values of nominal resistance are taken from the E24 series for resistors with a tolerance of 5%. The values of the E24 series are in accordance with “IEC publication 60063”. 10 5.0 2.0 1 ...

Page 5

... BCcomponents Professional power metal film resistors 10 5.0 2.0 1.0 PR02 2001 Jul 13 2.00 P (W) 1.50 1.00 0.50 0.5 0.2 0 Fig.2 Drift nomogram. 5 Product specification PR01/02/ amb o 100 C o 125 C o 155 C o 220 MLB683 ...

Page 6

... BCcomponents Professional power metal film resistors 10 5.0 2.0 1.0 PR03 2001 Jul 13 3.00 P (W) 2.25 1.50 0.75 0.5 0.2 0 Fig.3 Drift nomogram. 6 Product specification PR01/02/ amb o 100 C o 125 C o 155 C o 250 MLB693 ...

Page 7

... BCcomponents Professional power metal film resistors Limiting values TYPE LEAD MATERIAL PR01 Cu Cu PR02 FeCu Cu PR03 FeCu Note 1. The maximum voltage that may be continuously applied to the resistor element, see “IEC publication 60115-1”. The maximum permissible hot-spot temperature is 205 C for PR01, 220 C for PR02 and 250 C for PR03. ...

Page 8

... BCcomponents Professional power metal film resistors P ULSE LOADING CAPABILITIES 3 10 ˆ P max ( 1000 100 PR01 Fig.5 Pulse on a regular basis; maximum permissible peak pulse power a function of pulse duration (t 1200 V max (V) 1000 800 600 400 200 PR01 Fig.6 Pulse on a regular basis; maximum permissible peak pulse voltage ...

Page 9

... BCcomponents Professional power metal film resistors max 1000 ( 100 PR02 Fig.7 Pulse on a regular basis; maximum permissible peak pulse power a function of pulse duration (t 1700 V max (V) 1500 1300 1100 900 700 500 PR02 Fig.8 Pulse on a regular basis; maximum permissible peak pulse voltage ...

Page 10

... BCcomponents Professional power metal film resistors max ( 1000 p i 100 PR03 Fig.9 Pulse on a regular basis; maximum permissible peak pulse power a function of pulse duration (t 2400 V max (V) 2000 1600 1200 800 400 PR03 Fig.10 Pulse on a regular basis; maximum permissible peak pulse voltage ...

Page 11

... BCcomponents Professional power metal film resistors I NTERRUPTION CHARACTERISTICS ( The graph is based on measured data under constant voltage conditions; these data may deviate according to the application. PR01 Fig.11 Time to interruption as a function of overload power for range: 0R22 ( The graph is based on measured data under constant voltage conditions; ...

Page 12

... BCcomponents Professional power metal film resistors ( The graph is based on measured data under constant voltage conditions; these data may deviate according to the application. PR02 Fig.14 Time to interruption as a function of overload power for range: 0.33R ( The graph is based on measured data under constant voltage conditions; ...

Page 13

... BCcomponents Professional power metal film resistors Application information 200 T (K) 160 120 0.4 0.6 mm Cu-leads. PR01 Fig.18 Hot-spot temperature rise ( function of dissipated power. 200 T (K) 160 120 0.4 0.6 mm FeCu-leads. PR01 Fig.20 Hot-spot temperature rise ( function of dissipated power. 2001 Jul 13 MLB735 ...

Page 14

... BCcomponents Professional power metal film resistors 200 T (K) 160 120 0.8 0.8 mm Cu-leads. PR02 Fig.22 Hot-spot temperature rise ( function of dissipated power. 240 T (K) 200 160 120 0.8 0.6 mm FeCu-leads. PR02 Fig.24 Hot-spot temperature rise ( function of dissipated power. 2001 Jul 13 MLB679 100 ...

Page 15

... BCcomponents Professional power metal film resistors 240 T (K) 200 160 120 0.8 mm FeCu-leads. PR02 Fig.26 Hot-spot temperature rise ( function of dissipated power. 200 T (K) 160 120 0.8 mm Cu-leads. PR03 Fig.28 Hot-spot temperature rise ( function of dissipated power. 2001 Jul 13 CCB016 100 T ( (W) 0.8 mm FeCu-leads. ...

Page 16

... BCcomponents Professional power metal film resistors 240 T (K) 200 160 120 0.6 mm FeCu-leads. PR03 Fig.30 Hot-spot temperature rise ( function of dissipated power. 240 T (K) 200 160 120 0.8 mm FeCu-leads. PR03 Fig.32 Hot-spot temperature rise ( function of dissipated power. 2001 Jul 13 MLB691 100 T (K) ...

Page 17

... BCcomponents Professional power metal film resistors PR01 Fig.34 Impedance as a function of applied frequency. 120 (deg PR01 Fig.35 Phase angle as a function of applied frequency. 2001 Jul Product specification PR01/02/03 MLB659 100 (MHz) MLB658 100 (MHz) ...

Page 18

... BCcomponents Professional power metal film resistors PR02 Fig.36 Impedance as a function of applied frequency. 120 (deg 120 1 10 PR02 Fig.37 Phase angle as a function of applied frequency. 2001 Jul Product specification PR01/02/03 MLB769 124 (MHz) MLB770 124 (MHz) ...

Page 19

... BCcomponents Professional power metal film resistors PR03 Fig.38 Impedance as a function of applied frequency. 90 (deg PR03 Fig.39 Phase angle as a function of applied frequency. 2001 Jul Product specification PR01/02/03 MLB771 100 (MHz) MLB772 100 (MHz) ...

Page 20

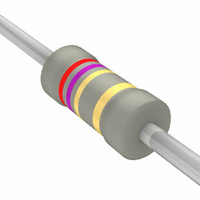

... FeCu 45 PR03 Cu 110 FeCu 100 Mounting The resistors are suitable for processing on automatic insertion equipment and cutting and bending machines. Marking The nominal resistance and tolerance are marked on the resistor using four coloured bands in accordance with IEC publication 60062, “Colour codes for fixed resistors” ...

Page 21

... BCcomponents Professional power metal film resistors P 0 Dimensions in mm. For dimensions see Tables 4 and 5. Table 5 Cropped and formed lead type and relevant physical dimensions; see Fig.41 TYPE LEAD STYLE PR01 PR02 cropped and formed; note 1 PR03 Note 1. Can be replaced by double kinked versions; see Fig.42. ...

Page 22

... BCcomponents Professional power metal film resistors P 0 Dimensions in mm. For dimensions see Tables 4 and 6. Table 6 Double kink lead type and relevant physical dimensions; see Fig.42 d TYPE LEAD STYLE (mm) double kink 0.58 0.05 large pitch PR01 double kink 0.58 0.05 small pitch ...

Page 23

... BCcomponents Professional power metal film resistors TESTS AND REQUIREMENTS Essentially all tests are carried out in accordance with the schedule of “IEC publication 60115-1”, category LCT/UCT/56 (rated temperature range: Lower Category Temperature, Upper Category Temperature; damp heat, long term, 56 days). The testing also covers the requirements specified by EIA and EIAJ ...

Page 24

... BCcomponents Professional power metal film resistors IEC IEC 60068-2 60115-1 TEST TEST CLAUSE METHOD 4.16 21 (U) robustness of terminations: 4.16.2 21 (Ua1) tensile all samples load 4.16.3 21 (Ub) bending half number of samples 4.16.4 21 (Uc) torsion other half of samples 4.20 29 (Eb) bump 4.22 6 (Fc) vibration 4 ...