MKS4-.22/100/10 WIMA, MKS4-.22/100/10 Datasheet - Page 7

MKS4-.22/100/10

Manufacturer Part Number

MKS4-.22/100/10

Description

Polyester Film Capacitors 100V .22uF 10%

Manufacturer

WIMA

Series

MKS 4r

Datasheet

1.MKS4-.4725010.pdf

(11 pages)

Specifications of MKS4-.22/100/10

Voltage Rating

100 Volts

Termination Style

Radial

Dimensions

3 mm W x 10 mm L x 8.5 mm H

Operating Temperature Range

- 55 C to + 100 C

Product

Metallized Polyester Film Capacitors

Capacitance

0.22 uF

Tolerance

10 %

Lead Spacing

7.5 mm

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

14

Recommendation for Processing

and Application of

Through-Hole Capacitors

A preheating of through-hole WIMA

capacitors is allowed for temperatures

T

In practice a preheating duration of

t 5 min. has been proven to be best.

Single wave soldering

Soldering bath temperature: T 260 ° C

Immersion time:

Double wave soldering

Soldering bath temperature: T 260 ° C

Immersion time:

Due to different soldering processes and

heat requirements the graphs are to be

regarded as a recommendation only.

ISO 9001:2000 is an international basic

standard of quality assurance systems for

all branches of industry. The approval

according to ISO 9001:2000 of our

factories by the VDE inspectorate certifies

that organisation, equipment and moni-

toring of quality assurance in our factories

correspond to internationally recognized

standards.

The WIMA Process Control System (WPCS)

is a quality surveillance and optimization

system developed by WIMA. WPCS is a

major part of the quality-oriented WIMA

production. Points of application of WPCS

during production process:

” incoming material inspection

” metallization

” film inspection

” schoopage

” pre-healing

” lead attachment

” cast resin preparation/

” 100% final inspection

” AQL check

WIMA Quality and Environmental Philosophy

Soldering Process

ISO 9001:2000 Certification

WIMA WPCS

max

encapsulation

100 ° C.

t 5 sec

2 x t 3 sec

All WIMA capacitors, irrespective of

whether through-hole devices or SMD,

are made of environmentally friendly

materials. Neither during manufacture

nor in the product itself any toxic

substances are used, e.g.

– Lead

– PCB

– CFC

– Hydrocarbon chloride

– Chromium 6+

We merely use pure, recyclable materials

for packing our components, such as:

” carton

” cardboard

” adhesive tape made of paper

” polystyrene

We almost completely refrain from using

packing materials such as:

” foamed polystyrene (Styropor®)

” adhesive tapes made of plastic

” metal clips

WIMA Environmental Policy

Wave soldering

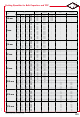

Typical temperature/time graph for double wave soldering

260

240

220

200

180

160

140

120

100

80

60

40

20

T

[°C]

enlargement

see detail-

30

60

10 s

– PBB/PBDE

– Arsenic

– Cadmium

– Mercury

– etc.

90

120

150

According to the RoHS Directive 2002/95/EC

certain hazardous substances like e.g. lead,

cadmium, mercury must not be used any

longer in electronic equipment as of July 1st,

2006. For the sake of the environment WIMA

has refraind from using such substances since

years already.

Tape for lead-free WIMA capacitors

WIMA’s environmental management has

been established in accordance with the

guidelines of DIN EN ISO 14001:2005.

The certification has been granted in

June 2006.

RoHS Compliance

DIN EN ISO 14001:2005

180

210

2 s

240 sec]

[

3 s

t

D