ADXL210AE-REEL Analog Devices Inc, ADXL210AE-REEL Datasheet - Page 11

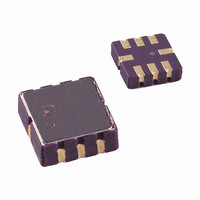

ADXL210AE-REEL

Manufacturer Part Number

ADXL210AE-REEL

Description

IC ACCELEROMETER LP 8-CLCC

Manufacturer

Analog Devices Inc

Datasheet

1.ADXL210EB.pdf

(12 pages)

Specifications of ADXL210AE-REEL

Axis

X, Y

Acceleration Range

±10g

Sensitivity

100mV/g

Voltage - Supply

3 V ~ 5.25 V

Output Type

Analog

Bandwidth

6kHz

Mounting Type

Surface Mount

Package / Case

8-CLCC

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Interface

-

Table V. Trade-Offs Between Microcontroller Counter Rate,

T2 Period, and Resolution of Duty Cycle Modulator

T2 (ms) (k ) Rate

1.0

1.0

1.0

5.0

5.0

5.0

10.0

10.0

10.0

USING THE ANALOG OUTPUT

The ADXL210E was specifically designed for use with its digital

outputs, but has provisions to provide analog outputs as well.

Duty Cycle Filtering

An analog output can be reconstructed by filtering the duty cycle

output. This technique requires only passive components. The

duty cycle period (T2) should be set to <1 ms. An RC filter with a

3 dB point at least a factor of >10 less than the duty cycle fre-

quency is connected to the duty cycle output. The filter resistor

should be no less than 100 kΩ to prevent loading of the output

stage. The analog output signal will be ratiometric to the supply

voltage. The advantage of this method is an output scale factor of

approximately double the analog output. Its disadvantage is that

the frequency response will be lower than when using the X

Y

X

The second method is to use the analog output present at the

X

output impedance and are not designed to drive a load directly.

An op amp follower may be required to buffer this pin. The

advantage of this method is that the full 5 kHz bandwidth of the

accelerometer is available to the user. A capacitor still must be

added at this point for filtering. The duty cycle converter should

be kept running by using R

ometer offset and sensitivity are ratiometric to the supply voltage.

The offset and sensitivity are nominally:

USING THE ADXL210E IN VERY LOW POWER

APPLICATIONS

An application note outlining low power strategies for the

ADXL210E is available. Some key points are presented here.

It is possible to reduce the ADXL210E’s average current from

0.6 mA to less than 20 µA by using the following techniques:

1. Power cycle the accelerometer.

2. Run the accelerometer at a lower voltage (down to 3 V).

FILT

FILT

FILT

, Y

output.

and Y

FILT

R

124

124

124

625

625

625

1250 100

1250 100

1250 100

SET

ADXL210E Sensitivity = (20 mV

Output

FILT

ADXL210E Clock

Sample

1000

1000

1000

200

200

200

pin. Unfortunately, these pins have a 32 kΩ

0 g Offset = V

Counter-

Rate

(MHz)

2.0

1.0

0.5

2.0

1.0

0.5

2.0

1.0

0.5

SET

<10 MΩ. Note that the acceler-

DD

Counts

per T2

Cycle

2000

1000

500

10000

5000

2500

20000

10000

5000

/2

Counts Resolution

per g

80

40

20

400

200

100

800

400

200

V

S

)/g

(mg)

12.50

25.00

50.00

2.50

5.00

10.00

1.25

2.50

5.00

FILT

,

Power Cycling with an External A/D

Depending on the value of the X

is capable of turning on and giving a good reading in 1.6 ms.

Most microcontroller-based A/Ds can acquire a reading in

another 25 µs. Thus it is possible to turn on the ADXL210E

and take a reading in <2 ms. If we assume that a 20 Hz sample

rate is sufficient, the total current required to take 20 samples is:

Running the part at 3 V will reduce the supply current from

0.6 mA to 0.4 mA, bringing the average current down to 16 µA.

The A/D should read the analog output of the ADXL210E at

the X

may be required in any case to amplify the analog output to give

enough resolution with an 8-bit to 10-bit converter.

Power Cycling When Using the Digital Output

An alternative is to run the microcontroller at a higher clock rate

and put it into shutdown between readings, allowing the use of the

digital output. In this approach the ADXL210E should be set at

its fastest sample rate (T2 = 0.5 ms), with a 500 Hz filter at X

and Y

possible and then shut down the ADXL210E and the microcon-

troller until the next sample is needed.

In either of the above approaches, the ADXL210E can be turned

on and off directly using a digital port pin on the microcontroller to

power the accelerometer without additional components.

CALIBRATING THE ADXL210E

The initial value of the offset and scale factor for the ADXL210E will

require calibration for applications such as tilt measurement. The

ADXL210E architecture has been designed so that these calibra-

tions take place in the software of the microcontroller used to decode

the duty cycle signal. Calibration factors can be stored in EEPROM

or determined at turn-on and saved in dynamic memory.

For low g applications, the force of gravity is the most stable,

accurate and convenient acceleration reference available. A reading

of the 0 g point can be determined by orientating the device

parallel to the earth’s surface and then reading the output.

A more accurate calibration method is to make measurements at

+1 g and –1 g. The sensitivity can be determined by the two

measurements.

To calibrate, the accelerometer’s measurement axis is pointed

directly at the earth. The 1 g reading is saved and the sensor is

turned 180° to measure –1 g. Using the two readings, the sensi-

tivity is:

For example, if the +1 g reading (A) is 55% duty cycle and the

–1 g reading (B) is 47% duty cycle, then:

These equations apply whether the output is analog or duty cycle.

Application notes outlining algorithms for calculating accelera-

tion from duty cycle and automated calibration routines are

available from the factory.

Let B = Accelerometer output with axis oriented to –1 g then:

FILT

FILT

Let A = Accelerometer output with axis oriented to +1 g

and Y

. The concept is to acquire a reading as quickly as

2 ms

Sensitivity = [55% – 47%]/2 g = 4%/g

FILT

20 Samples/s

pins. A buffer amplifier is recommended, and

Sensitivity = [A – B]/2 g

FILT

0.6 mA = 24 µA

capacitor, the ADXL210E

ADXL210E

FILT