AMS104Y Panasonic Electric Works, AMS104Y Datasheet - Page 5

AMS104Y

Manufacturer Part Number

AMS104Y

Description

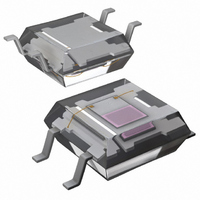

SENSOR LIGHT NAPICA 5V SMT 4SOP

Manufacturer

Panasonic Electric Works

Datasheet

1.AMS104Y.pdf

(6 pages)

Specifications of AMS104Y

Wavelength

580nm

Output Type

Current

Package / Case

4-SOP

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

255-1842-2

255-1848-2

255-1848-2

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

AMS104Y

Manufacturer:

PANASONIC

Quantity:

2 100

5. Recommended soldering

conditions

<SMD/Chip type>

1) Recommended condition

(1) IR (Infrared reflow) soldering method

T

T

T

t

t

(2) Soldering iron method

Tip temperature: 350 to 400°C

752°F

Wattage: 30 to 60 W

Soldering time: within 3 s

*We don’t recommend soldering iron

method for chip type.

2) Do not do flow soldering.

<Through-hole type>

1) Recommended condition

(1) Double wave soldering method

T

T

t

t

(2) Soldering iron method

Tip temperature: 350 to 400°C

752°F

Wattage: 30 to 60 W

Soldering time: within 3 s

11. The following shows the packaging format

1) SMD type tape and reel (mm inch)

1

2

1

2

Light sensor

NaPiCa

SMD type

AMS104Y

1

2

3

1

2

+t

= 60 to 120 s or less

= 30 s or less

= 120 s or less

= 150 to 180°C

= 230°C

= 250°C

= 120°C

= 260°C

3

T

T

T

T

T

= 6 s or less

3

2

1

2

1

Type

446°F

482°F

248°F

500°F

Note) When picked from 1 and 4-pin side

.059

.008

1.5

0.2

±.012

t

t

±0.3

1

1

or less

or less

302 to 356°F

±0.05

±.002

(Please inquire for tape and reel packaging with 2-pin and 3-pin on the

pull-out side.)

Anode side

Cathode side

.142

.094

3.6

2.4

t

2

t

2

±0.1

Device

mounted

on tape

±.004

±.004

±0.1

t

3

662 to

662 to

All Rights Reserved © COPYRIGHT Panasonic Electric Works Co., Ltd.

.157

.157

4.0

4.0

Tape dimensions

±.004

±0.1

±.004

±0.1

2) The soldered position on leads should

not be closer than 3mm

molding resin of this sensor.

6. Notes for mounting

1) Temperature rise in the lead portion is

highly dependent on package size.

If multiple different packages are

mounted on the same board, please

check your board beforehand in an actual

product, ensuring that the temperature of

the solder area of the sensor terminals

falls within the temperature conditions of

item 5.

2) If the mounting conditions exceed the

recommended solder conditions in item

5, resin strength will fall and the

mismatching of the heat expansion

coefficient of each constituent material

will increase markedly, possibly causing

cracks in the package, disconnections of

bonding wires, and the like. For this

reason, please inquire with us about

whether this use is possible.

7. Cleaning solvents compatibility

We recommend dip cleaning with an

organic solvent for removal of solder flux

etc. If you cannot avoid using ultrasonic

cleansing, please ensure that the

following conditions are met, and check

beforehand for defects.

• Frequency: 27 to 29 kHz

• Ultrasonic power: No greater than

• Cleaning time: No longer than 30 s

• Cleanser used: Asahiklin AK-225

• Other:

Note: Applies to unit area ultrasonic power for

0.25W/cm

Submerge in solvent in order to prevent

the PCB and sensors from being

contacted directly by the ultrasonic

vibrations.

Direction of

picking

ultrasonic baths.

2.0

.079

1.0

.039

±0.1

±.004

±0.1

±.004

2

dia.

dia.

1.5

.059

+0.1

−0

+.004

−0

1.75

.069

3.5

.138

dia.

dia.

±0.1

±0.1

±.004

±.004

8.0

.315

.118inch

±0.2

±.008

to the

Light Sensor (AMS1, 3, 4)

.079

2.0

±.020

±0.5

8. Transportation

Extreme vibration during transport will

warp the lead or damage the sensor.

Handle the outer and inner boxes with

care.

9. Avoid using the sensor in

environments containing excessive

amounts of steam, dust, corrosive

gas, or where organic solvents are

present.

10. Lead forming and cutting of

through-hole type

1) Lead forming must be done at normal

temperature before soldering

2) The bent and cut position on leads

should not be closer than 3mm

to the base of leads.

3) Lead forming and cutting must be

done while fixing the base of leads.

4) Avoid mounting with stress at the base

of leads.

Dimensions of tape reel

21.0

.827

13.0

.512

±0.8

±.031

±0.5

±.020

dia.

dia.

dia.

dia.

9.0

.354

11.4

.449

60

2.362

7.008

±0.3

.118inch

±0.5

178

±.012

±1.0

±.039

±.020

dia.

±2

±.079

dia.

dia.

dia.