BR42KB105M GE Sensing, BR42KB105M Datasheet

BR42KB105M

Specifications of BR42KB105M

Related parts for BR42KB105M

BR42KB105M Summary of contents

Page 1

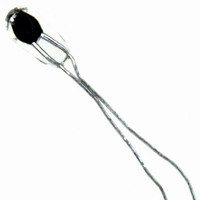

Sensing Features Type BR11/14/16/25 Small glass encapsulated bead thermistors on fine diameter alloy lead-wires. • Suitable for most low cost temperature measurement, control or compensation applications • Very fast thermal response times • Rugged glass encapsulation provides hermetic seal and ...

Page 2

GE Sensing Type BR Series Specifications Type BR11/14/16/23 Thermal and Electrical Properties The following lists the thermal and electrical properties for all small ruggedized thermistors. All definitions and test methods per MIL-PRF-23648. Body Dimensions BR11 • Nominal diameter: 0.011 in ...

Page 3

Sensing BR16 • Still air at 77F (25C): 0.12 mW/°C • Plunge into water: 0.60 mW/°C BR23 • Still air at 77F (25C): 0.18 mW/°C • Plunge into water: 0.9 mW/°C Power Rating (In Air) BR11 • Maximum Power Rating: ...

Page 4

GE Sensing Thermal Time Constant BR32 • Still air at 77°F (25°C): 4.5 second • Plunge into water: 90 msec BR42 • Still air at 77°F (25°C): 5 second • Plunge into water: 140 msec BR55 • Still air at ...