200-6310-9UN-1900 3M, 200-6310-9UN-1900 Datasheet - Page 2

200-6310-9UN-1900

Manufacturer Part Number

200-6310-9UN-1900

Description

SOCKET PGA ZIP 10X10 MATRIX

Manufacturer

3M

Series

Textool™r

Type

PGA, ZIF (ZIP)r

Datasheet

1.200-6315-9UN-1900.pdf

(2 pages)

Specifications of 200-6310-9UN-1900

Number Of Positions Or Pins (grid)

100 (10 x 10)

Mounting Type

Through Hole

Features

Closed Frame, Without Contacts

Contact Finish

Gold

Contact Finish Thickness

30µin (0.76µm)

Product

PGA Sockets

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Pitch

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

0 51138 69658 0

20063109UN1900

3M5066

5113869658

51138696580

JE150901237

20063109UN1900

3M5066

5113869658

51138696580

JE150901237

Test & Burn-In PGA Kit Socket

Pin Grid Arrays

3M Electronic Handling and Protection Division

6801 River Place Blvd.

Austin, TX 78726-9000

Ordering Information

Notes:

1 Contact and extra Hole Plugs are ordered separately.

2 See Test & Burn-In PGA socket section on page 29 for dimensional information on assembled sockets.

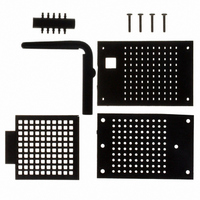

( Order Separately )

Contact

1

10X Hole Plugs

Cam Plate

Top Plate

Base Plate

200-6310-9UN-1900

200-6313-9UN-1900

200-6315-9UN-1900

200-6317-9UN-1900

200-6319-9UN-1900

200-6321-9UN-1900

200-6325-9UN-1900

300-6300-CNA-0002B

200-4660-14-1900

200-6311-9UN-1900

Part Number

4X Phillips Pan-Hd

#0-80 x 5/16 Long

Assy Screw

Cam Handle

For technical, sales or ordering information call 800-328-0411

Matrix Size

Set of 10

10 x 10

11 x 11

13 x 13

15 x 15

17 x 17

19 x 19

21 x 21

25 x 25

Each

Standard

Handle

or visit our website: http://www.3M.com/ehpd

Contact–BeCu/Au Plated

S k t Kit W/O C t t

Socket Kit W/O Contacts

Extra Hole Plugs

Description

1. Load hole plugs into top plate by

2. Place cam plate into recessed

3. Insert cam handle into position

4. Now make a final check that all

5. Now make an operation check

pressing fitting into place.

Remove from tie bar by cutting

with commercially available 6 1/2

flush diagonal cutter pliers.

area of base plate, load

contacts in desired locations,

being careful that the bent leaf

of the contact is loaded in

correct position ( away from

cam handle. )

in the base plate.

contacts are in desired location

and that all are fairly even at the

top. Also check cam to make

sure it is still in position. Now

take the top plate and place into

position and start to lower over

contacts. Start at the rear of the

socket and rotate downward

toward the front and then snap

locating bosses into place.

Several very slight back and

forth motions may be necessary

in order to get contacts to snap

into place. Care should be taken

that too much downward

pressure isn't applied which

could bend or damage the

contacts. Insert screws and

tighten.

by rotating handle 90

visual check of movement and

closure of all contacts. Rotate

handle and check the freedom

of movement of cam plate and

that the moving leaf of the

contact clears the entry hole. A

continuity check can be made

before final soldering by placing

device in socket, then closing

and making check. Soldering

should be done with socket in

the open position.

Assembly Instructions

∞

. Make a

TS-0675-09

Sheet 2 of 2

"