MKT1826510066 Vishay, MKT1826510066 Datasheet - Page 4

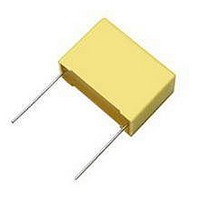

MKT1826510066

Manufacturer Part Number

MKT1826510066

Description

CAPACITOR POLYESTER FILM 1UF, 63V, RADIAL

Manufacturer

Vishay

Datasheet

1.MKT1826247014.pdf

(18 pages)

Specifications of MKT1826510066

Capacitor Application

Safety / Suppression

Capacitor Dielectric Type

Polyester

Capacitance Tolerance

± 20%

Voltage Rating

63VDC

Capacitor Case Style

Radial Leaded

Capacitance

1µF

Tolerance

20 %

Termination Style

Radial

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

FILM CAPACITORS

Plastic film capacitors are generally subdivided into film/foil

capacitors and metallized film capacitors.

FILM/FOIL CAPACITORS

Film/foil capacitors basically consist of two metal foiI electrodes

that are separated by an insulating plastic film also

called dielectric. The terminals are connected to the end-faces

of the electrodes by means of welding or soldering. Film/foil

capacitors are typically manufactured in C-values ranging from

100pF to 0.01µF.

Main features: High insulation resistance, excellent current car-

rying and pulse handling capability and a good capacitance

stability.

METALLIZED FILM CAPACITORS

The electrodes of metallized film capacitors consist of an

extremely thin aluminum layer (0.02µm - 0.1µm) that is vacuum

deposited either onto the dielectric film or onto a carrier film.

The dielectric film materials currently used in production range

from 0.9µm to 20µm. The opposing and extended metallized

film layers of the wound capacitor element are connected to

one another by flame spraying different metals to the end-

faces. The metal spraying process is also known as schooping.

The terminals are connected to the end-faces by means of

welding or soldering.

For the production of metallized film capacitors Vishay

Roederstein uses both the conventionally wound film and the

stacked film (multilayer) technology. Stacked film capacitors,

compared with wound film capacitors, exhibit a higher pulse

load.

Metallized film capacitors are typically manufactured in

C-values ranging from about 1000pF to 10µF.

Main features: High volume efficiency, self-healing properties.

SPECIAL CAPACITOR DESIGNS

For high current applications Vishay Roederstein is also able

to offer special designs such as capacitors with a heavy edge

metallization or a double sided metallization as well as

combinations that have a film/foil and a metallized film design

in one unit. For high voltage applications it is furthermore pos-

sible to offer designs with dual and multiple sections.

Depending on the design these capacitors provide low

losses, high current and pulse carrying capabilities, high volt-

ages, small dimensions and good self-healing properties.

General Technical Information

Vishay Roederstein

www.vishay.com

6

For technical questions, contact dc-film@vishay.com

Film Capacitors

SELF-HEALING

Self-healing, also known as clearing, is the removal of a de-

fect caused by pinholes, film flaws or external voltage

transients. The heat generated by the arcing during a break-

down, evaporates the extremely thin metallization of the film

around the point of failure, thereby removing and isolating the

short circuit conditions.

Stacked film capacitors exhibit due to their homogeneous and

their relatively low winding-pressure between the layers out-

standing self-healing properties.

The self-healing process requires only µW of power and a

defect is normally isolated in less than 10µs. Extensive and

continuous self-healing (e.g. at misapplications) will gradually

decrease the capacitance value.

DIELECTRIC MATERIALS

The electrical characteristics of plastic film capacitors are to a

great extent dictated by the properties of their dielectric mate-

rials. Vishay Roederstein uses the following film materials in

their production:

POLYETHYLENE TEREPHTALATE FILM OR

POLYESTER FILM (PET)

Polyester film offers a high dielectric constant, and a high di-

electric strength. It has further excellent self-healing pro- perties

and a good temperature stability. The temperature coefficient

of the material is positive.

Polyester capacitors are regarded as “general purpose ca-

pacitors”. They provide the best volume efficiency of all film

capacitors at moderate cost and are preferably used for DC

applications such as decoupling, blocking, bypassing and noise

suppressions.

POLYPROPYLENE FILM (PP)

Polypropylene film has superior electrical characteristics.

The film features very low dielectric losses, a high insulation

resistance, a low dielectric absorption, and a very high diel-

ectric strength. The film provides furthermore an excellent

moisture resistance and a very good long-term stability. The

temperature coefficient of the material is negative.

Polypropylene capacitors are typically used in AC and pulse

applications at high frequencies (e.g. fly-back tuning and

S-correction). They are further used in switched mode power

supplies, electronic ballasts and snubber applications, in fre-

quency discrimination and filter circuits as well as in energy

storage, and sample and hold applications.

POLYCARBONATE FILM (PC)

Polycarbonate film exhibits low dielectric losses, and a very

good long term stability. Its temperature coefficient is very low.

Polycarbonate film capacitors are preferably used in filter, tim-

ing and integrating applications.

Document Number 26033

Revision 01-Dec-03