51864-2 TE Connectivity, 51864-2 Datasheet - Page 13

51864-2

Manufacturer Part Number

51864-2

Description

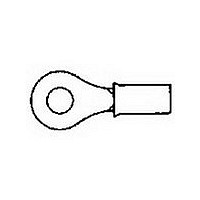

TERMINAL, RING TONGUE, #10, CRIMP, BLUE

Manufacturer

TE Connectivity

Type

Ring Tongue Terminalr

Series

PIDGr

Specifications of 51864-2

Stud Size

5mm

Wire Gauge

14-16

Body Plating

Tin

Body Material

Copper

Insulation

Nylon

Product Depth (mm)

7.92mm

Product Length (mm)

21.44mm

Color

Blue

Connector Type

Ring Tongue

Insulator Color

Blue

Termination Method

Crimp

Stud/tab Size

#10

Wire Size (awg)

16-14

Contact Material

Copper

Contact Plating

Tin

Rohs Compliant

Yes

Angle

Straight

Body Style

PIDG

Brand/series

PIDG

Cable Type

Regular Wire

Diameter, Insulation

0.105 to 0.15 "

Diameter, Stud

0.197 in.

Finish

Tin

Insulation Type

Nylon

Length, Overall

0.844 "

Material, Contact

Copper

Material, Insulation

Nylon

Material, Terminal

Copper

Package Quantity

100

Primary Type

Ring

Shape

RING-041

Size, Stud

10

Standards

RoHS Compliant, ELV Compliant

Thickness, Material

0.031 in.

Voltage Range

300 VAC

Width, Overall

0.312 "

Wire Size

16-14 AWG

Product

Rings

Stud / Tab Size

10

Gender

Female

Insulation Material

Nylon

Length

21.44 mm

Voltage Rating

300 VAC

Terminal Shape

Ring Tongue

Receptacle Style

Straight

Barrel Type

Closed Barrel

Wire/cable Type

Regular Wire

Insulation Support

Insulation Support

Insulation Diameter (mm [in])

2.67- 3.81 [.105-.150]

Stud Diameter (mm [in])

5.00 [0.197]

Heavy Duty

No

Voltage (vac)

300

Wire/cable Size (cma)

2,050 – 5,180

Wire Range (mm [awg])

1.25-2.00² [16-14]

Length (mm [in])

21.44 [0.844]

Tongue Material Thickness (mm [in])

0.79 [0.031]

Insulation Sleeve Material

Copper

Class

1 & 2

Government/industry Qualification

Yes

Government/industry Part Number

MS25036-108

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Loose Piece

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

51864-2

Manufacturer:

TE

Quantity:

20 000

6. VISUAL AID

Figure 11 shows a typical application of PIDG terminals, splices, and end caps. This illustration should be used

by production personnel to ensure a correctly applied terminal, splice, or end cap. Applications which DO NOT

appear correct should be inspected using the information in the preceding pages of this specification and in the

instructional material shipped with the product or tooling.

IF APPLICABLE, DOT CODE MUST BE

WELL FORMED AND CORRESPOND

WITH WIRE SIZE MARKING ON TOOLING

Rev

D

TERMINAL, SPLICE, OR END CAP

MUST BE STRAIGHT AND NOT

TWISTED ALONG AXIS

WIRE INSULATION MUST BE INSIDE

METAL SLEEVE OF TERMINAL,

SPLICE, OR END CAP

CRIMP MUST BE EVENLY

FORMED ACROSS CENTER

OF WIRE BARREL

FIGURE 11. VISUAL AID (CONT’D)

PIDG Terminals, Splices, and End Caps

INSULATION OF TERMINAL, SPLICE, OR END CAP

MUST BE FORMED OVER WIRE INSULATION

EACH WIRE MUST BE FLUSH

TO END OF WIRE BARREL

OR BOTTOMED ON STOP

INSULATION OF TERMINAL, SPLICE, OR END CAP

MUST BE EVENLY FORMED WITHOUT

OVERSTRESS MARKS

FRONT BELLMOUTH

MUST BE EVIDENT

WIRE MUST BE VISIBLE

AT END OF WIRE BARREL

INSULATION OF TERMINAL, SPLICE, OR

END CAP MUST NOT BE CUT OR TORN

WIRE MUST BE BOTTOMED

IN END CAP

END OF TERMINAL, SPLICE, OR

END CAP MUST NOT

BE BENT OR DEFORMED

114-2157

13

of 14