40523 TE Connectivity, 40523 Datasheet - Page 39

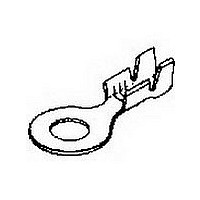

40523

Manufacturer Part Number

40523

Description

RING 12-10

Manufacturer

TE Connectivity

Type

Ring Tongue Terminalr

Datasheet

1.40523.pdf

(76 pages)

Specifications of 40523

Stud Size

4.16mm

Wire Gauge

10-12

Body Plating

Tin

Body Material

Brass

Insulation

Non-Insulated

Product Depth (mm)

8.71mm

Product Length (mm)

17.2mm

Color

Not Required

Rohs Compliant

YES

Terminal Shape

Ring Tongue

Receptacle Style

Straight

Barrel Type

Open Barrel

Wire/cable Type

Regular Wire

Insulation Support

Non-Insulation Support

Stud Diameter (mm [in])

4.17 [0.164]

Shape

RING-015

Heavy Duty

No

Finish

Tin

Wire Range (mm [awg])

3.00-6.00² [12-10]

Stock Thickness (mm [in])

1.02 [0.040]

Government/industry Qualification

No

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Strip

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Product Facts

I

I

I

I

I

I

I

I

Applications

I

I

I

I

I

Catalog 82227

Revised 8-04

www.tycoelectronics.com

Made from a continuous coil

of “Ribbon Connector”

material

Magnet wires MTM

Crimpband splices have

machine-piercing serrations

designed for displacing

magnet wire insulation

Available in brass, tin-

plated brass, and copper-

nickel alloy material

Make parallel or pigtail

connections on same

machine

100% of Crimpband

material is used in scrap

free terminations

Crimpband material coupled

with appropriate toolsets

accommodate specific

CMA ranges

Produced in Tyco Electronics

equipment on your

production floor

Meets UL 486C crimp

tensile requirements

Motors windings and

connections

Coil connections

Transformer windings and

connections

Lighting ballasts

Power supplies

Dimensions are in inches and

millimeters unless otherwise

specified. Values in brackets

are metric equivalents.

Machine Applied Terminations, Open Barrel Terminals

(Rings, Spades, Pins, Receptacles, Splices, Tabs)

MTM Crimpband Splices

Tyco Electronics features

the AMP MTM Crimpband

system that is comprised of

two key features: the semi-

automatic termination

machine and a reel of MTM

Crimpband material.

In a one-step crimping

operation, the machine

feeds, cuts, forms and

crimps the material to

provide a low-cost, high

reliability crimp connection.

The MTM Crimpband

splices are formed during

the crimping process from

Dimensions are shown for

reference purposes only.

Specifications subject

to change.

Mod I

machined longitudinal

grooved material that pierces

magnet wire varnish film

insulation during crimping.

MTM Crimpband splices

are specifically designed to

terminate magnet wire to

itself or in combination with

standard solid or stranded

lead wire.

Three magnet wires

maximum can be

terminated together with

stranded lead wire in one

splice.

USA: 1-800-522-6752

Canada: 1-905-470-4425

Mexico: 01-800-733-8926

C. America: 52-55-5-729-0425

Cut

Formed

Crimped

Tyco Electronics provides a

wide range of toolset types

and Crimpband splices to

meet various production

requirements.

Depending on your

specific application, MTM

Crimpband splices are

available in 7, 9, 11 and 13

serration versions for

terminations in the 400 to

13,000 CMA range.

When aluminum magnet wire

is used, MTM Crimpband

splices must be tin plated.

South America: 55-11-3611-1514

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

UK: 44-141-810-8967

Mod III

39