171661-2 TE Connectivity, 171661-2 Datasheet

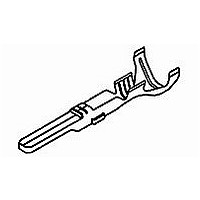

171661-2

Specifications of 171661-2

Available stocks

Related parts for 171661-2

171661-2 Summary of contents

Page 1

... Sealed Sensor Connector System 1. SCOPE 1.1. Content This specification covers performance, tests and quality requirements for the TE Connectivity (TE) Sealed Sensor Connector (SSC) system. 1.2. Qualification When tests are performed on the subject product line, procedures specified in Figure 1 shall be used. All inspections shall be performed using the applicable inspection plan and product drawing. ...

Page 2

Ratings ! Voltage: 125 volts AC/DC ! Current: See Figure 4 for applicable current carrying capability ! Operating Temperature: • Nylon housings: -40 to 150° C • PBT housings: -40 to 125° C 3.4. Performance and Test Description Product ...

Page 3

Test Description Disengaging force (terminal-terminal). Engaging force (terminal-connector). Engaging force (terminal-connector). Engaging force (connector-connector). Disengaging force (connector-connector). Locking plate (TPA) engaging force. Locking plate (TPA) disengaging force. Terminal bend resistance. Thermal shock. Rev B Requirement 2.5 Newtons minimum. 15 Newtons ...

Page 4

Test Description High temperature exposure. Humidity-temperature cycling. Immersion. Pressure/vacuum leak. Shall meet visual requirements, show no physical damage, and meet requirements of additional NOTE tests as specified in the Product Qualification and Requalification Test Sequence shown in Figure 2. Rev ...

Page 5

Product Qualification and Requalification Test Sequence Test or Examination Dry circuit resistance Voltage drop Isolation resistance Durability (10 cycles) Vibration (Profile) Mechanical shock Engaging force (terminal-terminal) Disengaging force (terminal-terminal) Insertion force (terminal-connector) Extraction force (terminal-connector) Mating force (connector-connector) Unmating ...

Page 6

QUALITY ASSURANCE PROVISIONS 4.1. Qualification Testing A. Specimen Selection Specimens shall be prepared in accordance with applicable Instruction Sheets and shall be selected at random from current production. Test groups 1, 2 and 3 shall each consist of 30 ...

Page 7

Number of Positions Vibration & Mechanical Shock Mounting Fixture Rev B Wire Size Rated Current (AWG) (amperes Reduction Coefficient ...

Page 8

Rev B Figure 6 Vibration Profile Figure 7 Contact Bend Fixture 108-1790 ...

Page 9

Rev B Figure 8 Humidity-Temperature Cycling Profile 108-1790 ...