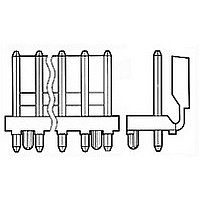

3-644615-5 TE Connectivity, 3-644615-5 Datasheet

3-644615-5

Specifications of 3-644615-5

Related parts for 3-644615-5

3-644615-5 Summary of contents

Page 1

... Application Specification (MTA 156 Connector) 3. REQUIREMENTS 3.1. Design and Construction Product shall be of the design, construction and physical dimensions specified on the applicable product drawing. 3.2. Materials ! Contact: • High force: Phosphor bronze, tin-lead plating • Standard: Phosphor bronze, tin-lead or gold over nickel plating ...

Page 2

... Application Specification 114-1020. ELECTRICAL 3 milliohms maximum initial. ∆R 5 milliohms maximum. 5000 megohms minimum initial. One minute hold with no breakdown or flashover. 30° C maximum temperatur e rise at specified current. MECHANICAL Solderable area shall have minimum of 95% solder coverage. Wire Size Slot Tensile AWG ...

Page 3

... See Figure 6. TE Spec 109-21-7. Subject mated samples to 3.15 G's rms between 5-500 Hz. Fifteen minutes in each of 3 mutually perpendicular planes. See Figure 6. TE Spec 109-26-1. Subject mated samples to 50 G's half-sine shock pulses of 11 milliseconds duration. Three shocks ...

Page 4

... Subject mated samples to 10 cycles between 25 and 65° 95% RH. TE Spec 109-43. Subject mated samples to temperature life at 105° C for gold plated contacts and 85° C for tin plated contacts for 1000 hours. TE Spec 109-85-3. Subject mated samples to environmental class III for 20 days ...

Page 5

... Discontinuities shall not be measured. Energize at 18 Test Specification 109-151. (e) Precondition samples with 5 cycles durability. Rev J Test Group ( Test Sequence (b) 1,9 1,9 1,8 1,5 1,3 3,7 2,7 2,4 2,6 3,7 3,8 2( level for 100% loadings per Figure 2 108-1051 6 1 ...

Page 6

... Samples shall be prepared in accordance with applicable Instruction Sheets and shall be selected at random from current production. Unless otherwise required for the test procedure, test groups and 4 shall consist of mated pairs of MTA 156 connectors and headers. Test group 1 shall consist position standard tin plated samples position high force tin plated samples; and 5, 6 position gold plated samples ...

Page 7

... Termination resistance equals millivolts divided by test current less resistance of wire length. NOTE (b) After wave soldering, printed circuit board and posts shall be cleaned to remove all flux and contaminates. Termination Resistance & Temperature Rise Measurement Points Rev J Figure 3 108-1051 ...

Page 8

... Base Rated Current for a single circuit at maximum ambient operating temperature as shown in Figure 4A. Rev J Figure 4A Current Carrying Capability Wire Size AWG 26 24 .501 .582 .685 .374 .435 .512 .253 .294 .346 Figure 4B Current Rating 108-1051 .820 1.0 .613 .746 .414 .504 ...

Page 9

Rev J Figure 5 Termination Tensile Strength 108-1051 ...

Page 10

Rev J Figure 6 Vibration & Mechanical Shock Mounting Fixture (Use For Reference Only) 108-1051 ...