3-647134-1 TE Connectivity, 3-647134-1 Datasheet - Page 3

3-647134-1

Manufacturer Part Number

3-647134-1

Description

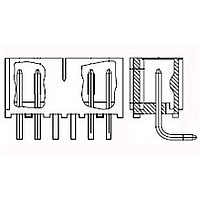

11P MTA156 SHRD HDR ASSY LF

Manufacturer

TE Connectivity

Specifications of 3-647134-1

Connector Type

Header

Product Line

MTA-156

Pcb Mounting Orientation

Right Angle

Right Angle Bending Side

Rear

Pcb Mount Retention

Without

Mating Connector Lock

Without

Four Points Of Contact

Without

Shrouded

Yes

Mounting Ears

Without

Post Size (mm [in])

1.14 [.045]

Panel Mount Retention

Without

Current Rating (a)

7

Voltage Rating (vac)

600

Solder Tail Contact Plating

Bright Tin

Termination Post Length (mm [in])

3.18 [0.125]

Number Of Positions

11

Centerline (mm [in])

3.96 [0.156]

Narrow

No

Post Number(s) Omitted

None

Contact Type

Pin

Contact Shape

Square

Contact Plating, Mating Area, Material

Gold (30) or (30) Total Gold Flash over Palladium Nickel

Contact Base Material

Copper Alloy

Connector Style

Plug

Housing Color

Black

Mating Alignment

Without

Ul Flammability Rating

UL 94V-0

Housing Material

Polyester

Backwall/post Interruption(s)

Without

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Wave solder capable to 240°C

Rohs/elv Compliance History

Always was RoHS compliant

Applies To

Printed Circuit Board

Application Use

Wire-to-Board

Termination tensile strength,

perpendicular, unmated.

Vibration, sinusoidal.

Vibration, random.

Mechanical shock.

Durability.

Mating force.

Unmating force.

Thermal shock.

Rev J

Test Description

No discontinuities of 1 microsecond

or longer duration.

See Note.

No discontinuities of 1 microsecond

or longer duration.

See Note.

No discontinuities of 1 microsecond

or longer duration.

See Note.

See Note.

Standard contact: 1.75 pounds

maximum per contact.

High force contact: 6 pounds

maximum per contact.

Gold contact: 1.25 pounds

maximum per contact.

Standard contact: .2 pound

minimum per contact.

High force contact: .7 pound

minimum per contact.

Gold contact: .1 pound minimum

per contact.

See Note.

Wire Size

AWG

26

24

22

20

18

Figure 1 (continued)

ENVIRONMENTAL

Requirement

Pounds Minimum

Slot Tensile

1.3

1.3

3.4

4.0

4.6

TE Spec 109-16.

Determine slot tensile strength by

pulling perpendicular to terminated

wire at maximum rate of 1 inch per

minute.

See Figure 5.

TE Spec 109-21-1.

Subject mated samples to 10-55-10

Hz traversed in 1 minute with 0.06

inch maximum total excursion. Two

hours in each of 3 mutually

perpendicular planes.

See Figure 6.

TE Spec 109-21-7.

Subject mated samples to 3.15 G's

rms between 5-500 Hz. Fifteen

minutes in each of 3 mutually

perpendicular planes.

See Figure 6.

TE Spec 109-26-1.

Subject mated samples to 50 G's

half-sine shock pulses of 11

milliseconds duration. Three shocks

in each direction applied along 3

mutually perpendicular planes, 18

total shocks.

See Figure 6.

TE Spec 109-27.

With header mounted in fixture,

manually mate and unmate

samples for 25 cycles.

TE Spec 109-42, Condition A.

Measure force necessary to mate

samples with header at maximum

rate of .5 inch per minute. Calculate

force per contact.

TE Spec 109-42, Condition A.

Measure force necessary to unmate

samples from header at maximum

rate of .5 inch per minute. Calculate

force per contact.

TE Spec 109-22.

Subject mated samples to 25 cycles

between -55 and 105° C.

Procedure

108-1051

3 of 10