583861-3 TE Connectivity, 583861-3 Datasheet

583861-3

Specifications of 583861-3

Related parts for 583861-3

583861-3 Summary of contents

Page 1

... Performance and Test Description Connectors shall be designed to meet the electrical, mechanical and environmental performance requirements specified in Figure 1. ©2011 Tyco Electronics Corporation, | Indicates Change a TE Connectivity Ltd. Company *Trademark All Rights Reserved TE logo is a trademark. For latest revision, visit out website at www.te.com/documents For Regional Customer service, visit our website at www ...

Page 2

Test Requirements and Procedures Summary Test Description Examination of Product Termination Resistance, Specified Current Termination Resistance, Dry Circuit Dielectric Withstanding Voltage Insulation Resistance Current Cycling Crimp Resistance Vibration Physical Shock Test Description Rev D Requirement Meets requirements of product ...

Page 3

Mating Force Contact Retention (Crimped Contacts) Contact Engaging Force Contact Separating Force Crimp Tensile Durability Thermal Shock Humidity, Steady State Rev D 12 ounces maximum per contact pair. Contacts shall not dislodge from normal locking position. 10 ounces maximum per ...

Page 4

Connector Qualification and Requalification Tests and Sequences Test or Examination Examination of Product Termination Resistance, Current Termination Resistance, Dry Circuit Dielectric Withstanding Voltage Insulation Resistance Crimp Resistance Current Cycling Vibration Physical Shock Connector Mating Force Contact Retention Contact Engaging ...

Page 5

C. Acceptance 1. Test results from development on pre-qualification samples will be used to determine upper and lower one-sided statistical tolerance limits for 99% reliability at 95% confidence, as follows. Let Xbar and s denote the sample average and standard ...

Page 6

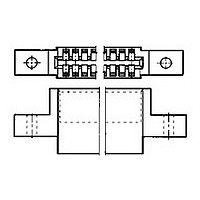

Dimensions are in inches. NOTES 2. Unless otherwise specified, tolerance is +/-.005. 3. The test card shall extend 4.00 +/-.02 from the receptacle after insertion. 4. Number of contacts shall be the same as on the corresponding printed wiring ...

Page 7

Rev D Figure 5 Termination Resistance Test Circuit Figure 6 Crimp Resistance 108-9031 ...

Page 8

Tolerances: +/-.005 unless otherwise indicated. NOTES 2. Material: Tool steel, hardened to Rockwell C50-55. 3. Gage surface shall be clean of contaminants or lubricants. Rev D Gage A B Number 1 .0700 (a) 2 .0540 (a) Figure 7 Printed ...