640432-2 TE Connectivity, 640432-2 Datasheet - Page 4

640432-2

Manufacturer Part Number

640432-2

Description

WIRE-BOARD CONN RECEPTACLE, 2POS, 3.96MM

Manufacturer

TE Connectivity

Series

MTA-156 Seriesr

Specifications of 640432-2

Peak Reflow Compatible (260 C)

No

Wire Size (awg)

20

Leaded Process Compatible

No

Mounting Type

PCB

Connector Type

Wire-to-Board

Rohs Compliant

No

Product Type

Receptacles / Sockets - Housings

Contact Gender

Socket (Female)

Pitch

3.96 mm

Number Of Positions / Contacts

2

Number Of Rows

1

Mounting Style

Wire

Termination Style

IDC

Wire Gauge Range

20

Housing Material

Nylon

Contact Material

Copper Alloy

Contact Plating

Tin Lead

Voltage Rating

600 VAC

Current Rating

7 A

Connector Design

Closed End

Product Line

MTA-156

Termination Method To Wire/cable

IDC Standard

Wire Size (mm² [awg])

0.5-0.6² [20]

Mating Connector Lock

Without

Four Points Of Contact

Without

Shrouded

No

Mounting Ears

Without

Panel Mount Retention

Without

Current Rating (a)

7

Voltage Rating (vac)

600

Solder Tail Contact Plating

Tin-Lead

Number Of Positions

2

Centerline (mm [in])

3.96 [0.156]

Narrow

No

Post Number(s) Omitted

None

Cable Exit Angle

90°

Contact Type

Socket

Contact Plating, Mating Area, Material

Tin-Lead

Contact Base Material

Copper Alloy

Connector Style

Receptacle

Housing Color

Yellow

Mating Alignment

Without

Ul Flammability Rating

UL 94V-2

Rohs/elv Compliance

Not ELV/RoHS compliant

Lead Free Solder Processes

Not relevant for lead free process

Applies To

Wire/Cable

Application Use

Wire-to-Board

Lead Free Status / Rohs Status

No

3.6.

Rev F

Examination of product

Termination resistance, dry circuit

Termination resistance, specified current

Insulation resistance

Dielectric withstanding voltage

Temperature rise vs current

Current cycling

Tensile strength, straight and perpendicular (c)

Vibration

Durability

Contact retention

Mating force

Unmating force

Thermal shock

Humidity-temperature cycling

Product Qualification and Requalification Test Sequence

NOTE

(a) See paragraph 4.1.A.

(b) Numbers indicate sequence in which tests are performed.

(c)

Test or Examination

One half of the samples shall be subjected to the straight tensile test and the remaining

half to the perpendicular tensile test.

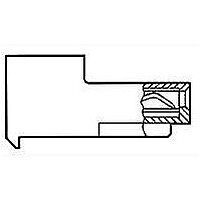

Figure 2

1

1

2,4

1,5

2

6

3

2,5

1,4

3

3

Test Sequence (b)

Test Group (a)

2,4

4

3

1

5

1,3

5

2

1,3

6

2

7

1

108-1065

8

1

4 of 7