640432-6 TE Connectivity, 640432-6 Datasheet

640432-6

Specifications of 640432-6

Related parts for 640432-6

640432-6 Summary of contents

Page 1

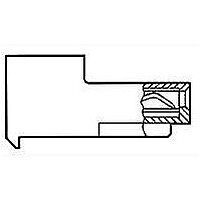

... Connector, MTA 156, Wire-To-Wire System 1. SCOPE 1.1. Content This specification covers the performance requirements for the TE Connectivity (TE) MTA 156 connector wire-to-wire system. This system provides a reliable interconnection between wires in appliances, vending machines, computers and other sophisticated commercial equipment. 1.2. Qualification When tests are performed on the subject product line, procedures specified in Figure 1 shall be used. ...

Page 2

Performance and Test Description Product shall be designed to meet the electrical, mechanical and environmental performance requirements specified in Figure 1. 3.5. Test Requirements and Procedures Summary Test Description Examination of product. Termination resistance, dry circuit. Termination resistance, specified ...

Page 3

Test Description Tensile, perpendicular. Vibration. Durability. Contact retention. Mating force. Unmating force. Thermal shock. Humidity-temperature cycling. Shall meet visual requirements, show no physical damage, and shall meet requirements of NOTE additional tests as specified in the Test Sequence in Figure ...

Page 4

Product Qualification and Requalification Test Sequence Test or Examination Examination of product Termination resistance, dry circuit Termination resistance, specified current Insulation resistance Dielectric withstanding voltage Temperature rise vs current Current cycling Tensile strength, straight and perpendicular (c) Vibration Durability ...

Page 5

QUALITY ASSURANCE PROVISIONS 4.1. Qualification Testing A. Sample Selection Connector housings and contacts shall be prepared in accordance with applicable Instruction Sheets and shall be selected at random from current production. Test group 1 shall consist of 1 connector ...

Page 6

A 1 foot minimum length of continuous lead for heat dissipation. NOTE 2. Termination resistance equals millivolts divided by test current less resistance of 6 inches of wire. Temperature and Resistance Measurement Points Rev F Figure 3 108-1065 6 ...

Page 7

Rev F Figure 4 Terminal Temperature vs Current/Circuit 24 Circuit Assembly 108-1065 ...