2007637-5 TE Connectivity, 2007637-5 Datasheet - Page 3

2007637-5

Manufacturer Part Number

2007637-5

Description

CAGE, STACKED, 2X2, SFP+, LIGHT

Manufacturer

TE Connectivity

Datasheet

1.2007637-5.pdf

(10 pages)

Specifications of 2007637-5

Connector Type

Cage

Contact Termination

Press Fit

Connector Mounting

PCB

Contact Plating

Gold

Contact Material

Copper Alloy

Connector Mounting Orientation

PCB

Rohs Compliant

Yes

No. Of Contacts

4

Svhc

No SVHC (15-Dec-2010)

Product Type

Cage

Termination Type

Press-Fit

Configuration

2 x 2

Pcb Mount

Single Sided

Termination Post Length (mm [in])

3.00 [0.118]

Contact Plating, Mating Area, Material

Gold or Gold Flash over Palladium Nickel

Contact Base Material

Copper Alloy

Cage Type

Stacked

Housing Color

Black

Ul Flammability Rating

UL 94V-0

Housing Material

Liquid Crystal Polymer (LCP)

Cage Material

Nickel Silver

Emi Containment

External Springs

Lightpipe

With

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Application

SFP+

Lightpipe Configuration

Four Per Column

Packaging Method

Tray

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

2007637-5

Manufacturer:

TYCO

Quantity:

36 560

3. REQUIREMENTS

3.1. Safety

Do not stack component packages so high that the shipping containers buckle or deform.

3.2. Limitations

The connectors are designed to operate in a temperature range of --55_ to 105_C [--67_ to 221_F].

The bezel requirements given in this document are specifically configured for products used in the

communications industry. It is strongly recommended that this bezel configuration NOT be used for peripheral

component interconnect (PCI) applications.

3.3. Material

The connector housing and chicklets (parts that hold the compliant pin contacts) are made of molded

thermoplastic, UL 94--V--0. All compliant pin contacts in the connector are made of copper alloy underplated

with nickel; plated with tin at the leads and plated with gold or gold equivalent at the interface area. The cage

assembly is made of copper alloy. The EMI/Dust Plug is made of die cast zinc.

3.4. Storage

3.5. Chemical Exposure

3.6. PC Board

Rev B

NOTE

A. Ultraviolet Light

Prolonged exposure to ultraviolet light may deteriorate the chemical composition used in the connector

material.

B. Shelf Life

The connector and cage assembly should remain in the shipping container until ready for use to prevent

deformation to the compliant pin contacts and mounting posts. The connector and cage assemblies should

be used on a first in, first out basis to avoid storage contamination that could adversely affect

performance.

Do not store connector and cage assemblies near any chemical listed below as they may cause stress

corrosion cracking in the compliant pin contacts or mounting posts.

Alkalies

Amines

A. Material and Thickness

The pc board material shall be glass epoxy (FR--4 or G--10). The minimum pc board thickness shall be

1.5 mm.

B. Tolerance

Maximum allowable bow of the pc board shall be 0.08 mm over the length of the connector and cage

assembly.

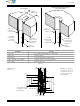

C. Hole Dimensions

The holes for the connector signal contacts and cage assembly must be drilled and plated through to

dimensions specified in Figure 2.

D. Layout

The holes for the connector and cage assembly must be precisely located to ensure proper placement and

optimum performance of the connector and cage assembly. Recommended hole pattern, dimensions, and

tolerances are provided on the customer prints. Sample layouts are provided in Figure 3.

i

Contact Product Information at the number at the bottom of page 1 for suitability of other board materials.

Ammonia

Carbonates

Citrates

Nitrites

Phosphates Citrates

Sulfur Nitrites

Sulfur Compounds

Tartrates

114- 13219

3 of 10