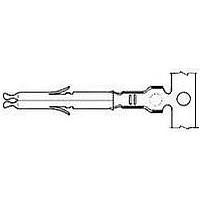

170362-1 TE Connectivity, 170362-1 Datasheet

170362-1

Specifications of 170362-1

Available stocks

Related parts for 170362-1

170362-1 Summary of contents

Page 1

ProductType Specification 1.25mm Pitch FFC Connector (Non-ZIF Type) 1.0 SCOPE 1.1 Contents This specification covers the requirements for product performance, test methods and quality assurance provisions of 1.25mm Pitch FFC Connector (Non-ZIF type). 2.0 APPLICABLE DOCUMENTS The following documents form ...

Page 2

Materials A. Contact: Phosphor Bronze, 0.8µm Min. Tin or Tin-Lead over 1.27µm Min. Nickel underplate B. Housing: Glass-Filled PBT, UL94V-0 3.3 Ratings A. Voltage Rating: B. Current Rating: C. Temperature Range: D. Storage Temperature Range: - ...

Page 3

Temperature Rise Max. under specified Current current load. 3.5.6 Vibration No electrical discontinuity (Low Frequency) greater than 1 µsec. shall occur. TR M ax. (Final) 3.5.7 Physical Shock No electrical discontinuity greater than ...

Page 4

Cable Mating Force Pos. x 1.96N (200gf) Max. (First cycle) 3.5.10 Cable Unmating Pos. x 0.49N (50gf) Min. (First Force cycle) 3.5.11 Contact Retention 3.92N (0.4 kgf) Min. Force 3.5.12 Durability TR M ax. (Final) (Repeated ...

Page 5

Insulation resistance: 3.5.17 Humidity- 100 M M in.(Final) Temperature Cycling Termination resistance M in.(Final) Insulation resistance: 3.5.18 Humidity, Steady 100 M M in.(Final) State Termination resistance M in.(Final) 3.5.19 Salt Spray TR: ...

Page 6

Product Qualification and Requalification Tests Test Examination Confirmation of Product Termination Resistance (Low Level) Dielectric Strength Insulation Resistance Temperature Rise Vs Current Vibration (Low Frequency) Physical Shock Hammering Shock Cable Mating Force Cable Unmating Force Contact Retention Force Durability ...

Page 7

Test Examination Confirmation of Product Termination Resistance (Low Level) Dielectric Strength Insulation Resistance Temperature Rise Vs Current Vibration (Low Frequency) Physical Shock Hammering Shock Cable Mating Force Cable Unmating Force Contact Retention Force Durability (Repeated Mate/Unmating) Solderability Resistance to Soldering ...

Page 8

Quality Assurance Provisions 4.1 Test Conditions Unless otherwise specified, all the tests shall be performed in any combination of the following test conditions Temperature: 15~30°C Relative Humidity: 45~75% Atmosphere Pressure: 650~800mm Hg 4.2 Test Specimens 4.2.1 The test specimens ...

Page 9

Rev G 108-51021 ...

Page 10

Rev G 108-51021 ...