CRA06S08031911FRT1 Vishay, CRA06S08031911FRT1 Datasheet - Page 3

CRA06S08031911FRT1

Manufacturer Part Number

CRA06S08031911FRT1

Description

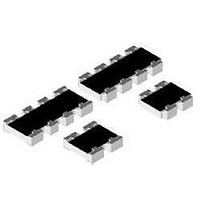

Resistor Networks & Arrays 1.91Kohms 1% 8Pin

Manufacturer

Vishay

Series

CRA06Sr

Datasheet

1.CRA06S08320K0JTA.pdf

(4 pages)

Specifications of CRA06S08031911FRT1

Product Type

Arrays

Circuit Type

Isolated

Number Of Resistors

4

Resistance

1.91 KOhms

Tolerance

1 %

Temperature Coefficient

+/- 100 PPM / K

Operating Temperature Range

- 55 C to + 150 C

Dimensions

1.5 mm W x 1.6 mm L x 0.5 mm H

Termination Style

SMD/SMT

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

CRA06E, CRA06S

Vishay

Notes

(1)

(2)

www.vishay.com

254

TEST PROCEDURES AND REQUIREMENTS

TEST

(clause)

Resistance (4.5)

Temperature coefficient (4.8.4.2)

Overload (4.13)

Solderability (4.17.5)

Resistance to soldering heat (4.18.2)

Rapid change of temperature (4.19)

Damp heat, steady state (4.24)

Climatic sequence (4.23)

Endurance at 70 °C (4.25.1)

Extended endurance (4.25.1.8)

Endurance at upper category

temperature (4.25.3)

APPLICABLE SPECIFICATIONS

• EN 60115-1

• EN 140400

• EN 140401-802

• IEC 60068-2-X

• EIA 481

Figures are given for a single element

Solderability is specified for 2 years after production or requalification. Permitted storage time is 20 years

(2)

Generic Specification

Sectional Specification

Detail Specification

Variety of environmental test procedures

Packaging of SMD components

For technical questions, contact: filmresistors.thickfilmchip@vishay.com

CONDITIONS OF TEST

Stability for product types:

16 h at UCT = 125 °C; 1 cycle at 55 °C;

U = U

U = U

30 min at UCT = 125 °C; 5 cycles

solder bath method; 235 °C; 2 s

Aging 4 h at 155 °C, dryheat

Duration extended to 8000 h

Thick Film Resistor Array

1 h/1 kPa at 15 °C to 35 °C;

30 min at LCT = - 55 °C;

(260 ± 5) °C; (10 ± 1) s

max.

max.

UCT = 125 °C; 1000 h

U = 2.5 × (P

1.5 h ON; 0.5 h OFF;

(40 ± 2) °C; 56 days;

2 h at LCT = - 55 °C;

Solder bath method;

visual examination

20/- 55/20 °C and

≤ 2 x U

5 cycles at 55 °C

; whichever is less severe

; whichever is less severe

U = (P

U = (P

(93 ± 3) % RH

70 °C; 1000 h

20/125/20 °C

max.

70

70

-

EN 60115-1

x R)

x R)

70

CRA06E/CRA06S

; 0.5 s

x R)

1/2

1/2

1/2

CLASS 1 OR BETTER

± (0.25 % R + 0.05 Ω)

± (0.25 % R + 0.05 Ω)

± (0.25 % R + 0.05 Ω)

± (1 % R + 0.05 Ω)

± (1 % R + 0.05 Ω)

± (1 % R + 0.05 Ω)

± (1 % R + 0.05 Ω)

± (2 % R + 0.1 Ω)

10 Ω to 1 MΩ

± 100 ppm/K

STABILITY

PERMISSIBLE CHANGE (ΔR/R)

± 1 %

Good tinning (≥ 95 % covered)

REQUIREMENTS

no visible damage

Document Number: 31002

CLASS 2 OR BETTER

± (0.5 % R + 0.05 Ω)

± (0.5 % R + 0.05 Ω)

± (0.5 % R + 0.05 Ω)

± (2 % R + 0.1 Ω)

± (2 % R + 0.1 Ω)

± (2 % R + 0.1 Ω)

± (4 % R + 0.1 Ω)

± (2 % R + 0.1 Ω)

10 Ω to 1 MΩ

± 2 %; ± 5 %

± 200 ppm/K

Revision: 13-Oct-08

STABILITY

(1)