BCS2015A1 TDK Corporation, BCS2015A1 Datasheet

BCS2015A1

Specifications of BCS2015A1

Related parts for BCS2015A1

BCS2015A1 Summary of contents

Page 1

... Visible Radiant Optical Sensor /Data Sheet TDK Visible Radiant Optical Sensor is the photo-IC which uses an amorphous silicone semiconductor technology. It is the most suitable for Brightness Adjustment, Control of the Lighting systems. BCS2015A1 has current- amplifire in it. BCS2015A1 is for surface mounthing. Features • Highly receptive to visible light but not receptive to infrared light (close to Human eye visibility). • ...

Page 2

... Output characteristic(typical):BCS2015A1 1.E-02 1.E-03 1.E-04 1.E-05 1.E-06 1.E-07 1 Measuring circuit diagram Light Optical sensor Vop=3V Vop=4V Vop=5V 10 100 1,000 Illuminance(Lx Vop V V-meter - 10,000 100,000 I-meter 2 ...

Page 3

... BCS2015A1 Characteristic of Output Voltage (Typical) Measuring circuit 4.5 4 3.5 3 2.5 2 1.5 1 0.5 0 100 Photo- Illuminance dependency of Max. Vo (Typical) Vcc=5V Vcc=3V 1000 Illuminance(Lx) Vcc 10000 ...

Page 4

Vcc=5V 1.E+00 1.E-01 1.E-02 1.E-03 1.E+00 1.E+01 1.E+01 1.E+00 Vcc=3V 1.E-01 1.E-02 1.E-03 1.E+00 1.E+01 RL=4k ohm RL=55k ohm RL=630k ohm 1.E+02 1.E+03 Illuminamce(Lx) 1.E+02 1.E+03 Illuminance(Lx) 1.E+04 RL=950 ohm RL=20k ohm RL=260k ohm 1.E+04 ...

Page 5

... Typical photo response time:BCS2015A1 (typ.) 1.E-02 1.E-03 1.E-04 1.E+03 Measuring circuit + LED pulse light - Optical sensor tr tf 1.E+04 Load Resistor RL (Ω) 5V Vout Vout RL 1.E+05 2V 90% 10 ...

Page 6

... Temperature stability of output current:BCS2015A1 (typical) 1.2 1.1 1 0.9 0.8 0.7 0.6 -10 0 Spectral response:BCS2015A1 (typical) 1.0 0.8 0.6 0.4 0.2 0.0 300 Temperature(deg.C) Human eyes (CIE standard) 400 500 Wave length(nm) *VR=5V FL 100Lux BCS2015A1 600 700 800 3 ...

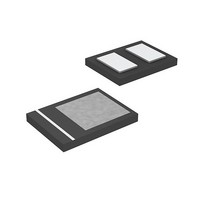

Page 7

Recommended land pattern Recommended land pattern is shown in Fig. shown in Fig. to the direction of curvature as the result of heat stress by reflow and/or physical stress. Recommanded reflow heat condition For Pb-Flee soldering process 245deg./C - 255deg./C ...