1996771-1 TE Connectivity, 1996771-1 Datasheet

1996771-1

Manufacturer Part Number

1996771-1

Description

CONN PIN CONTACT GOLD

Manufacturer

TE Connectivity

Series

-r

Type

Coaxialr

Specifications of 1996771-1

Pin Or Socket

Pin, Center

Contact Termination

Solder

Wire Gauge

Coaxial Cable, 0.047"

Contact Finish

Gold

Contact Finish Thickness

-

Current Rating

-

Product Type

Connector - RF

Rf Connector Type

SMPM

Mount

Floating Panel

Cable Type

.047 Semi-Rigid

Termination Type

Solder

Dielectric Material

Fluoropolymer

Impedance (?)

50

Mount Type

Cable Mount

Plating Material

Gold over Nickel

Contact Base Material

Beryllium Copper

Contact Plating, Mating Area, Material

Gold over Nickel

Center Contact Material

Beryllium Copper

Center Contact Plating

Gold over Nickel

Housing Material

Beryllium Copper

Vita 67

Yes

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Hand solderable with tin/lead solder

Rohs/elv Compliance History

Always was RoHS compliant

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

A103871

1. INTRODUCTION

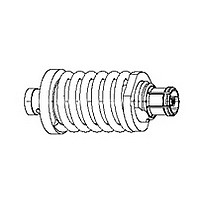

SMPM Floating Panel Mount Cable Jacks (Direct

Solder Attachment) shown in Figure 1 are designed to

be soldered to semi--rigid, conformable, or flexible

coaxial cable with a diameter of 2.16 mm [.085 in.] or

1.19 mm [.047 in.]

The cable jacks are designed to be inserted into a

mounting hole (such as the one in VITA 67, daughter

card module 1996705--3).

2. DESCRIPTION

The cable jacks consists of a body, compression

spring, retaining washer, and center contact. The

compression spring and retaining washer are used to

secure the part into the module. See Figure 1.

3. ASSEMBLY PROCEDURE

E2010 Tyco Electronics Corporation, Berwyn, PA

All Rights Reserved

TE logo and Tyco Electronics are trademarks.

*Trademark. Other products names, logos, or company names might be trademarks of their respective owners.

CAUTION

NOTE

1. Strip the cable to the dimensions shown in

Figure 2.

2. For flexible cable, tin the cable braid.

3. Shape the blunt end of the center conductor to a

cone between 85 and 90. See Figure 3.

4. Insert the cable center conductor into the center

contact inside the rear shell of the cable plug until

the cable bottoms. No braid strands should be

exposed. See Figure 4.

5. Holding the cable center conductor in place and

using 60/40 solder, attach the rear shell to the

cable as shown in Figure 4.

Washer

i

!

Dimensions in this instruction sheet are in

millimeters [with inches in brackets]. Figures and

illustrations are for reference only and are not

drawn to scale.

DO NOT nick the center conductor of the cable.

Take care not to cut the cable braid.

Figure 1

Compression Spring

TOOLING ASSISTANCE CENTER 1- - 800- - 722- - 1111

PRODUCT INFORMATION 1- - 800- - 522- - 6752

Cable Jack

SMPM Floating Panel Mount, Cable Jacks

(Direct Solder Attachment)

1996390- 1, 1996771- 1

4. INSERTING CONNECTOR INTO MODULE

DANGER

1. Insert soldered cable connector into module

mounting hole from the flange side of the module

bottoming the connector body flange on the

module. See Figure 5.

80+10_ Typ

2.03 [.080]

5.33 [.210]

2.03 [.080]

0.25 [.010] Max Typ

Flat (Radius Optional)

Semi- - Rigid and Conformable Cables

To avoid personal injury, make sure to follow all

local practices and safety precautions when

working with soldering equipment.

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.tycoelectronics.com

85- - 90_

Stripping Dimensions

Flexible Cable

Center

Conductor

Figure 2

Figure 3

Figure 4

Center

Conductor

Braid

Cable Center

Conductor

408- - 10373

Instruction Sheet

Outer

Conductor

06 AUG 10 Rev B

Jacket

Solder Here

Cable

1 of 2

LOC B

Related parts for 1996771-1

1996771-1 Summary of contents

Page 1

... TE logo and Tyco Electronics are trademarks. *Trademark. Other products names, logos, or company names might be trademarks of their respective owners. SMPM Floating Panel Mount, Cable Jacks (Direct Solder Attachment) 1996390- 1, 1996771- 1 Cable Jack Semi- - Rigid and Conformable Cables 0.25 [.010] Max Typ Flat (Radius Optional) 2 ...

Page 2

Insert compression spring in module mounting hole and over connector body from the module mating face. 3. Place retaining washer into insertion tool 2101595--1 aligning the flats on the tool with the external flats on the washer. 4. Align ...