lt3825 Linear Technology Corporation, lt3825 Datasheet

lt3825

Available stocks

Related parts for lt3825

lt3825 Summary of contents

Page 1

... A third transformer winding provides output voltage feedback. The LT3825 is a current mode controller that regulates output voltage based on sensing secondary voltage via a transformer winding during fl yback. This allows for tight output regulation without the use of an optoisolator, improving dynamic response and reliability ...

Page 2

... LT3825EFE#TRPBF LEAD BASED FINISH TAPE AND REEL LT3825EFE LT3825EFE#TR Consult LTC Marketing for parts specifi ed with wider operating temperature ranges. For more information on lead free part marking, go to: For more information on tape and reel specifi cations, go to: ELECTRICAL CHARACTERISTICS ...

Page 3

... Continuous operation above the specifi ed maximum operating junction temperature may impair device reliability. Note 3: The LT3825E is guaranteed to meet performance specifi cations from 0°C to 125°C. Specifi cations over the –40°C to 125°C operating – ...

Page 4

... LT3825 TYPICAL PERFORMANCE CHARACTERISTICS V and V CC(0N) CC(OFF) vs Temperature CC(ON CC(OFF –50 – 100 TEMPERATURE (°C) 3825 G01 SENSE Voltage vs Temperature 110 FB = 1.1V 108 + SENSE = V SENSE – WITH SENSE 106 104 102 100 –50 – ...

Page 5

... Load Capacitance 25° FALL TIME 40 30 RISE TIME 125 CAPACITANCE (nF) LT3825 Feedback Amplifi Temperature 1100 1050 SINK = 1.4V 1000 950 900 100 125 –50 – TEMPERATURE (°C) 3825 G11 I Hysteresis vs Temperature UVLO 3.7 3.6 3.5 3 ...

Page 6

... LT3825 TYPICAL PERFORMANCE CHARACTERISTICS Minimum PG On Time vs Temperature 340 R = 158k tON(MIN) 330 320 310 300 290 280 270 260 –50 – 100 TEMPERATURE (°C) 3825 G19 PIN FUNCTIONS SG (Pin 1): Synchronous Gate Drive Output. This pin provides an output signal for a secondary-side synchro- nous switch. Large dynamic currents may fl ...

Page 7

... See the Applications Information for details. GND (Exposed Pad, Pin 17): This is the ground connection for both signal ground and gate driver grounds. This GND should be connected to the PCB ground plane. Careful at- tention must be paid to ground layout. See Applications – Information for details. LT3825 at C 3825fa 7 ...

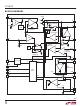

Page 8

... LT3825 BLOCK DIAGRAM UVLO 19. – 1.235V 15.3V REFERENCE ( UVLO 10 I UVLO OSC 7 OSCILLATOR SYNC PGDLY 15 ENDLY 4 8 CLAMPS 0.7 + 1.3 – 3V INTERNAL REGULATOR UVLO – COMPARATOR TSD CURRENT TRIP SLOPE COMPENSATION SET ENABLE LOGIC BLOCK PGATE SGATE – ...

Page 9

... FLYBACK FEEDBACK AMPLIFIER LT3825 FEEDBACK AMP 1.25V – + COLLAPSE DETECT ENABLE TIMING DIAGRAM PRIMARY SIDE MOSFET DRAIN VOLTAGE PG VOLTAGE SG VOLTAGE V FLBK – 3825 FFA V FLBK MIN ENABLE ON(MIN) ENABLE DELAY FEEDBACK AMPLIFIER ENABLED ...

Page 10

... This precludes the need of an optoisolator in isolated designs greatly improving dynamic response and reliability. The LT3825 has a unique feedback amplifi er that samples a transformer winding voltage during the fl yback period and uses that voltage to control output voltage. ...

Page 11

... These include effective transconductance and V node slew rate. C Load Compensation Theory The LT3825 uses the fl yback pulse to obtain information about the isolated output voltage. An error source is caused by transformer secondary current fl ow through the synchronous MOSFET R impedances of the transformer secondary and output capacitor. This was represented previously by the ex- pression “ ...

Page 12

... LT3825 OPERATION LOAD COMP CMPF 50k – CMP CMP Figure 1. Load Compensation Diagram FB node. This effectively increases the voltage required at the top of the R1/R2 feedback divider to achieve equilibrium. The average primary side switch current increases to main- tain output voltage regulation as output loading increases ...

Page 13

... DS(ON) The feedback winding usually provides both the feedback voltage and power for the LT3825. So set the turns ratio between the output and feedback winding to provide a rectifi ed voltage that under worst-case conditions is greater than the 11V maximum V turn-off voltage ...

Page 14

... LT3825 APPLICATIONS INFORMATION As a rough guide, leakage inductance of several percent (of mutual inductance) or less may require a snubber, but exhibit little to no regulation error due to leakage spike behavior. Inductances from several percent up to perhaps ten percent cause increasing regulation error. Avoid double digit percentage leakage inductances as there is a potential for abrupt loss of control at high load current ...

Page 15

... Designing a transformer for such a situation is beyond the scope of this document. For multiple windings, realize that the fl yback winding signal is a combination of activity on all the secondary windings. Thus load regulation is affected by each windings load. Take care to minimize cross regulation effects. LT3825 : MIN • ...

Page 16

... LT3825 APPLICATIONS INFORMATION Setting Feedback Resistive Divider The expression for V developed in the Operation sec- OUT tion is rearranged to yield the following expression for the feedback resistors • ESR + R +I OUT SEC R1 • Continuing the example, if ESR + R 3.32k, then • 0.008 R1= 3.4k – ...

Page 17

... S(OUT) load compensation (from step 2). Setting Frequency The switching frequency of the LT3825 is set by an external capacitor connected between the OSC pin and ground. Recommended values are between 200pF and 33pF , yielding switching frequencies between 50kHz and 250kHz. Figure 2 shows the nominal relationship between external capacitance and switching frequency ...

Page 18

... The enable delay time should be made long enough to ignore the “irrelevant” portion of the fl yback waveform at light load. Even though the LT3825 has a robust gate drive, the gate transition time slows with very large MOSFETs. Increase delay time as required when using such MOSFETs. ...

Page 19

... Figure 3c shows an alternate method of fi ltering by split- ting the R A put more of the resistance on the UVLO side. Converter Start- The standard topology for the LT3825 utilizes a third . The design A transformer winding on the primary side that provides both referred voltage IN feedback information and local V (see Figure 4). This power “ ...

Page 20

... UVLO function becomes counterproductive. In such cases it is better to operate the LT3825 directly from the available supply this case, use the LT3837 which is identical to the LT3825 except that it lacks the internal V supplies most function designed to operate directly from supplies TR ...

Page 21

... DC is greater than 50%. In some switcher con- trollers, slope compensation reduces the maximum peak current at higher duty cycles. The LT3825 eliminates this problem by having circuitry that compensates for the slope compensation so that maximum current sense voltage is constant across all duty cycles ...

Page 22

... So divide the load current by (1 – DC). If the output load current is relatively constant, the feedback resistive divider is used to compensate for these losses. Otherwise, use the LT3825 load compensation circuitry (see Load Compensation). If multiple output windings are used, the fl yback winding will have a signal that represents an amalgamation of all these windings impedances ...

Page 23

... C MILLER • f OSC – V The LT3825 gate drives will clamp the max gate voltage TH to roughly 7.5V, so you can safely use MOSFETs with max V of 10V or larger. GS LT3825 = 7.5V for this part vs temperature curve. If you don’ ...

Page 24

... LT3825 APPLICATIONS INFORMATION Synchronous Gate Drive There are several different ways to drive the synchronous gate MOSFET. Full converter isolation requires the synchro- nous gate drive to be isolated. This is usually accomplished by way of a pulse transformer. Usually the pulse driver is used to drive a buffer on the secondary as shown in the application on the front page of this data sheet ...

Page 25

... Refer to the PC Board Layout section for more details Thermal Considerations = 3mΩ Take care to ensure that the LT3825 junction temperature does not exceed 125°C. Power is computed from the aver- age supply current, the sum of quiescent supply current (I in the specifi cations) plus gate drive currents. ...

Page 26

... JA impedance (40°C/W). PC Board Layout Considerations In order to minimize switching noise and improve output load regulation, connect the GND pin of the LT3825 directly to the ground terminal of the V CC the bottom terminal of the current sense resistor, the ground terminal of the input capacitor, and the ground plane (multiple vias) ...

Page 27

... For applications with multiple switching power converters connected to the same input supply, make sure that the input fi lter capacitor for the LT3825 is not shared with other converters. AC input current from another converter de- could cause substantial input voltage ripple and this could CC interfere with the LT3825 operation ...

Page 28

... LOAD CURRENT (A) 28 48V Isolated Supply 47k P6SMB100A 1/4W + MBRS1100 47μF 0.1μF 20V Si4490DY SENSE LT3825 – SENSE V C SYNC R ENDLY OSC GND SFST C CMP CMP 2.1k 0.22μF 100k 1% 47pF 0.1μ 200μH (i.e 200nH/T ) PINS 32T OF 2 × 32AWG PINS 11T OF 1 × ...

Page 29

... PG SG SENSE CC LT3825 – SENSE V C SYNC R ENDLY OSC GND SFST C CMP CMP 866Ω 0.22μF 62k 1% 47pF 0.1μ 3825 TA03b LT3825 T1 PULSE PB2134 4 7 • 150μF 6TPB150ML • 1 ×3 10 • B0540W 47Ω FMMT618 Si7892DP FMMT718 SG 0.04Ω ...

Page 30

... Isolated Supply 100pF 250V BAS21 47k 20Ω 20Ω 1/4W + Si4490DY 47μ SENSE CC 0.02Ω 1/2W LT3825 – SENSE V C ENDLY OSC GND SFST C 10nF CMP CMP 10k 0.01μF 150k 47pF 0.1μF 1nF Q1: ZETEX FMMT618 Q2: ZETEX FMMT718 T1: PULSE PA1477NL 11 12 ...

Page 31

... REF 0° – 8° 0.65 (.0256) BSC 4. RECOMMENDED MINIMUM PCB METAL SIZE FOR EXPOSED PAD ATTACHMENT (INCHES) *DIMENSIONS DO NOT INCLUDE MOLD FLASH. MOLD FLASH SHALL NOT EXCEED 0.150mm (.006") PER SIDE LT3825 4.90 – 5.10* (.193 – .201) 3.58 (.141) 16 1514 6.40 2.94 (.252) (.116) ...

Page 32

... LT3825 RELATED PARTS PART NUMBER DESCRIPTION LT1424-5 Isolated Flyback Switching Regulator LT1424-9 Isolated Flyback Switching Regulator LT1425 Isolated Flyback Switching Regulator LTC1698 Isolated Secondary Synchronous Rectifi er Controller LT1725 General Purpose High Power Isolated Flyback Controller LT1737 High Power Isolated Flyback Controller ...