MBB02070C1104FRP00 Vishay, MBB02070C1104FRP00 Datasheet - Page 10

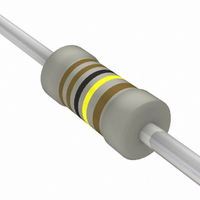

MBB02070C1104FRP00

Manufacturer Part Number

MBB02070C1104FRP00

Description

RES 1.10M OHM METL FILM .60W 1%

Manufacturer

Vishay

Series

MBB 0207r

Specifications of MBB02070C1104FRP00

Temperature Coefficient

±50ppm/°C

Resistance (ohms)

1.1M

Power (watts)

0.6W

Composition

Metal Film

Tolerance

±1%

Size / Dimension

0.098" Dia x 0.256" L (2.50mm x 6.50mm)

Lead Style

Through Hole

Package / Case

Axial

Resistance In Ohms

1.10M

Case

Axial

Resistance

1.1Mohm

Resistance Tolerance

± 1%

Power Rating

600mW

Voltage Rating

300V

Resistor Element Material

Metal Film

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Features

-

Height

-

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Contains lead / RoHS non-compliant

Other names

2312 815 11105

2312 915 11105

B0207C1M100F5TBC

BC1.10MZTR

2312 915 11105

B0207C1M100F5TBC

BC1.10MZTR

TESTS AND REQUIREMENTS

Essentially all tests are carried out in accordance with the

following specifications:

EN 60115-1, generic specification (includes tests)

EN 140100, sectional specification (includes schedule for

qualification approval)

EN 140101-806 (successor of CECC 40101-806), detail

specification (includes schedule for conformance inspection)

The Test and Requirements table contains only the most

important tests. For the full test schedule refer to the

documents listed above. The testing also covers most of the

requirements specified by EIA/IS-703 and JIS-C-5202.

The tests are carried out in accordance with IEC 60068-2-xx

test method and under standard atmospheric conditions in

accordance with IEC 60068-1, 5.3. Climatic category

LCT/UCT/56 (rated temperature range: Lower category

Document Number: 28766

Revision: 23-Jul-10

TEST PROCEDURES AND REQUIREMENTS

CLAUSE

4.5

4.8

4.25.1

4.25.3

4.24

60115-1

IEC

METHOD

60068-2-

78 (Cab)

TEST

IEC

−

-

-

-

-

MBA/SMA 0204, MBB/SMA 0207, MBE/SMA 0414 - Professional

operation mode

operation mode

upper category

Endurance at

Temperature

temperature

steady state

Damp heat,

Resistance

Endurance

Endurance

coefficient

Long term

Standard

at 70 °C:

at 70 °C:

TEST

For technical questions, contact:

Professional Thin Film Leaded Resistors

At (20/LCT/20) °C and

Stability for product

types:

(40 ± 2) °C; 56 days;

1.5 h ON; 0.5 h OFF

1.5 h ON; 0.5 h OFF

U =

U =

(20/UCT/20) °C

125 °C; 1000 h

155 °C; 1000 h

PROCEDURE

70 °C; 8000 h

(93 ± 3) % RH

70 °C; 1000 h

70 °C; 1000 h

70 °C; 8000 h

MBB/SMA 0207

MBA/SMA 0204

MBE/SMA 0414

U = U

U = U

P

P

70

70

max.

max.

x R

x R

;

;

or

or

± (0.25 % R + 0.05 Ω)

filmresistorsleaded@vishay.com

± (0.5 % R + 0.05 Ω)

± (0.5 % R + 0.05 Ω)

temperature, upper category temperature; damp heat,

steady state, test duration: 56 days) is valid.

Unless otherwise specified the following values apply:

Temperature: 15 °C to 35 °C

Relative humidity: 45 % to 75 %

Air pressure: 86 kPa to 106 kPa (860 mbar to 1060 mbar).

For performing some of the tests, the components are

mounted on a test board in accordance with IEC 60115-1,

4.31.

In Test Procedures and Requirements table, only the tests

and requirements are listed with reference to the relevant

clauses of IEC 60115-1 and IEC 60068-2-xx test methods. A

short description of the test procedure is also given.

1 Ω to 2.4 MΩ

1 Ω to 332 kΩ

1 Ω to 1 MΩ

STABILITY

CLASS 0.5

± (0.25 % R + 0.05 Ω)

± (0.5 % R + 0.05 Ω)

± (0.5 % R + 0.05 Ω)

± (1 % R + 0.05 Ω)

PERMISSIBLE CHANGE (ΔR max.)

± 5 % R; ± 1 % R; ± 0.5 % R

± 50 ppm/K; ± 25 ppm/K

± (0.5 % R + 0.05 Ω)

REQUIREMENTS

± (1 % R + 0.05 Ω)

± (1 % R + 0.05 Ω)

0.22 Ω to < 1 Ω

0.22 Ω to < 1 Ω

0.22 Ω to < 1 Ω

STABILITY

CLASS 1

(2)

(1)

(4)

(3)

Vishay Beyschlag

STABILITY

± 0.25 % R

www.vishay.com

± 0.5 % R

± 0.5 % R

CLASS 2

> 2.4 MΩ

> 332 kΩ

± 1 % R

± 1 % R

± 2 % R

± 2 % R

> 1 MΩ

31