75003-0010 Molex Inc, 75003-0010 Datasheet - Page 3

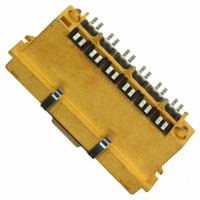

75003-0010

Manufacturer Part Number

75003-0010

Description

CONN PLUG 24POS 1.2MM VERT SMD

Manufacturer

Molex Inc

Series

Plateau HS Mezz™ 75003r

Datasheets

1.75005-0306.pdf

(7 pages)

2.75005-0306.pdf

(9 pages)

3.75005-0306.pdf

(12 pages)

4.75003-0010.pdf

(8 pages)

Specifications of 75003-0010

Connector Type

Differential Pair Array, Male

Number Of Positions

24

Pitch

0.047" (1.20mm)

Number Of Rows

2

Mounting Type

Surface Mount

Features

Board Guide

Contact Finish

Gold

Contact Finish Thickness

30µin (0.76µm)

Mated Stacking Heights

15mm, 17mm, 25mm

Height Above Board

0.522" (13.25mm)

Pitch Spacing

1.2mm

No. Of Contacts

24

Gender

Plug

Contact Plating

Gold

No. Of Rows

2

Contact Termination

Surface Mount Vertical

Product Type

Receptacles

Mounting Style

Wire

Number Of Positions / Contacts

4

Housing Material

High Temperature Thermoplastic

Contact Material

High Performance Alloy (HPA)

Voltage Rating

30 V

Current Rating

1.5 A

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

075003-0010

075003-0010-C

0750030010

0750030010-C

75003-0010-C

750030010

750030010-C

WM17213

075003-0010-C

0750030010

0750030010-C

75003-0010-C

750030010

750030010-C

WM17213

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

75003-0010

Manufacturer:

Molex, LLC

Quantity:

12 000

REVISION:

DOCUMENT NUMBER:

4.0 INSERTION AND WITHDRAWAL

C

connectors. It also describes the special zippering feature of this connector which allows for the full rotation of

the connector about a specific point of rotation.

This section describes the preferred methods for inserting and withdrawing the High Speed Mezzanine

4.1 Preferred Method of Insertion and Withdrawal:

AS-75005-001

ECR/ECN INFORMATION:

EC No:

DATE:

UCP2003-2204

2003 / 04 / 09

APPLICATION SPECIFICATION

Figure 2

HIGH SPEED MEZZANINE

Figure 1

TITLE:

CREATED / REVISED BY:

Ken Stiles

BOARD TO BOARD CONNECTOR SYSTEM

APPLICATION SPECIFICATION FOR THE

WITHDRAWAL

INSERTION

HIGH SPEED MEZZANINE

Rotation

Rotation

Point

Point

Figure 1 is the preferred method of insertion. Straight

insertion of the connectors insures proper alignment

during the mating process.

Zippering during Insertion:

The “zippering” together of the connectors during

insertion is permissible. This can reduce the amount of

force required to insert the connector. However, to do

this the mating connector must be properly placed at the

point of rotation. See Figure 2.

requires more force during the withdrawal

process.

Zippering during Withdrawal:

Zippering the connector during the withdrawal

process is the preferred method of withdrawing the

connector. This allows for reduced withdrawal

forces. The connector is designed to rotate fully

about its point of rotation during the withdrawal

process, without binding or damaging the

components of the connector.

The connector may also be withdrawn evenly with

out damaging any components of the connector.

This method is less preferable only because it

CHECKED BY:

Ken Stiles

TEMPLATE FILENAME: PRODUCT_SPEC[SIZE_A](V.1).DOC

Manny Banakis

APPROVED BY:

SHEET No.

3

of

9