BS-33-8 3M, BS-33-8 Datasheet - Page 3

BS-33-8

Manufacturer Part Number

BS-33-8

Description

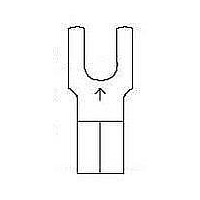

Terminals BLK FORK 12-10 AWG 8

Manufacturer

3M

Series

MVUr

Datasheet

1.BS-22-6.pdf

(90 pages)

Specifications of BS-33-8

Wire Size (awg)

12-10

Stud / Tab Size

# 10

Insulation

Not Insulated

Gender

Male

Termination Style

Solder Lug

Length

1.20 mm

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

5400728816

Standard Terminal Construction

3M Terminals provide a variety of design features assuring

consistently effective, reliable performance and easy

installation.

for the attributes described below.

1. One-piece, burr-free construction provides maximum

2. Barrel-to-pad transition design minimizes flexing

3. Open-end design permits visual inspection of wire

4. Maximum hold on wire comes from multiple “V”

5. Injection-molded insulations on terminals are the highest

6. Crimp ridge designed for positive location of tool on

7. Funnel barrel construction provides:

8. Nylon-insulated terminals, with grip, feature a brass

9. Non-slip ridge so tool slides to correct position for a

10.Beveled leading edge for easy wire insulation entry.

Please refer to the illustrations at the numbered locations

• Positive, easy wire insertion

• No hang-ups of wire strands

• Wire twisting not necessary

electrical conductivity. Electrical bright-tin plating gives

maximum corrosion resistance. Annealing relieves stress

points and assures maximum installed strength.

and bending.

location before and after crimping.

grooves in #26-4 AWG parts, resulting in excellent

current flow.

quality in the industry.

terminal barrel, resulting in few miscrimps.

sleeve. Sleeve provides optimum grip on insulation,

strain relief and vibration protection. Brass sleeve is

recessed, which provides excellent flash-over protection.

proper crimp and better workmanship.

4

6

8

2

• 221°F (105°C) rated, tough, resistant electrical

• Molding ensures consistent wall thickness for

• Molding allows funnel barrel construction for

• Molding offers the crimp ridge and non-slip ridge

grade materials

maximum reliability after crimping

easier installation

10

7

3

5

9

1

Vinyl

Insulated

6

8

4

2

10

7

3

5

1

9

Nylon Insulated

with Insulation

Grip

Barrel Styles

Non-insulated butted seam

The most economical terminal, it is

used where special performance or

installation characteristics are not

needed. Beveled mouth facilitates wire insertion.

Maximum temperature for bare terminals: 347°F (175°C).

Non-insulated brazed seam

Beveled mouth facilitates wire

insertion. Can be crimped anywhere

on barrel surface. Silver brazed seam

will not open under crimping pressure

or operating stresses. Unlike butted seam parts, stranded

wire cannot escape barrel confines during, or after, crimping.

Maximum temperature for bare terminals: 347°F (175°C).

Vinyl insulated brazed and butted seams

Used where insulated barrel

is necessary and desirable.

Terminal consists of brazed

or butted part with flared,

rigid molded polyvinyl

chloride sleeve, securely attached and funneled for easy wire

entry. Wire insulation positions itself against funnel portion

of vinyl sleeve, eliminating strand hang-up. Crimping barrel

and flared portion of sleeve provide excellent electrical

contact plus mechanical stress relief at junction of insulation

and barrel. Insulation has a non-slip ridge for ease of

positioning crimping tool.

Insulators are rated at a continuous operating temperature

range from -40°F to 221°F (-40°C to 105°C).

and 1,000V signs and lighting fixtures (luminaries).

Nylon insulated butted seam

with insulation grip

Used where insulated barrel

and positive insulation grip

are necessary or desirable.

Terminal consists of butted

seam part with flared, seamless brass sleeve securely

attached and covered with flared, molded nylon sleeve. Wire

insulation positions itself against funnel portion of brass

sleeve. Crimping barrel and flared portion of sleeve provide

excellent electrical contact plus mechanical stress relief at

junction of insulation and barrel. Positioning crimp tool is

nearly mistake proof due to a “step” in nylon insulation.

Insulators are rated at a continuous operating temperature

range from -40°F to 221°F (-40°C to 105°C).

and 1,000V signs and lighting fixtures (luminaries).

Industry standard color coding indicates wire range.

UL Listed and CSA Certified for 600V building wire

Industry standard color coding indicates wire range.

UL Listed and CSA Certified for 600V building wire

3