BS-33-8 3M, BS-33-8 Datasheet - Page 4

BS-33-8

Manufacturer Part Number

BS-33-8

Description

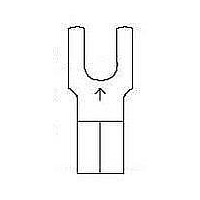

Terminals BLK FORK 12-10 AWG 8

Manufacturer

3M

Series

MVUr

Datasheet

1.BS-22-6.pdf

(90 pages)

Specifications of BS-33-8

Wire Size (awg)

12-10

Stud / Tab Size

# 10

Insulation

Not Insulated

Gender

Male

Termination Style

Solder Lug

Length

1.20 mm

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

5400728816

4

Correct crimping is important

to assure a strong connection

Insulated Terminals and

Connectors:

Non-Insulated Terminals

and Connectors:

Indent should be opposite

the barrel seam.

Heat Shrink Terminals, Connectors

and Disconnects

3M Heat Shrink pre-insulated terminals, connectors

and disconnects protect against the most challenging

of environments, making the best moisture protection

available. They offer several advantages over conventional

unsealed products.

material, when properly crimped and shrunk, provides a seal

that is resistant to water, salt, steam and other related

contaminants.

lined heat shrink tubing adheres, when shrunk, to both the

connector and the wire insulation, providing improved

pullout strength and strain relief.

Installation Procedure

Funnel Barrel Feature provides an excellent electrical

and mechanical connection.

• Funnel design guides wire into position.

• No wire strand hang-up as the wire is inserted, giving

• Wire is in place, ready for crimping.

For maximum crimping performance, barrel of connector

must be properly indexed in the crimp tool station.

Corrosion Resistance – The adhesive-lined heat shrink

Improved Mechanical Performance – The adhesive-

Durable Heat Shrink Tubing – Tough heat shrink

a fast, positive installation.

Electrical Crimp

Mechanical

Crimp

Correct

Incorrect

Note: All dimensions are measured in inches.

Clearance

tubing effectively resists abrasion, scoring, cut-through,

and the effects of long term aging.

splices and disconnects are available in wire sizes 22–10

AWG, and can be installed easily with a recommended tool

and heat source. The connectors are color-coded for wire

range identification, and the transparent tubing allows for

visual inspection.

High Temperature Terminals

and Connectors

3M high temperature terminals and connectors are

constructed of steel with a nickel plating. Their temperature

rating for continuous use at 900°F (482°C) makes them

perfect for use in ovens, motors, light fixtures and other

applications where other connectors would corrode or melt.

temperature steel parts.

Application Procedure for

Heat Shrink Products:

1. Strip wires to appropriate

length as indicated on package

label.

2. Insert wire into terminal

and crimp with correct

station of a recommended tool.

3. Apply heat with a

recommended heat source.

Standard Crimp Terminal

and Connector Specifications

Materials

Crimp terminals and connectors are to be burr-free, annealed

and bright-tin plated ETP copper. Barrels shall be 0.25" long

with brazed seams where specified. Insulation grip sleeves

are to be tin-plated brass and attached securely to the barrel.

Terminal insulators are to be molded polyvinyl chloride or

nylon, UL Listed and CSA Certified for 600V in building

wire and 1,000V in signs and lighting fixtures (luminaries).

Connector insulators are to be extruded polyvinyl chloride

or nylon with a temperature rating of 221°F (105°C).

Construction

All insulated terminals are to have funnel entry construction

to prevent strand hang-up and a crimp ridge for proper tool

location. Nylon insulated terminals and connectors are to

have butted seam barrels with insulation grip sleeves. All

terminal barrels are to have multiple “V” grooves for

maximum conductor retention.

Versatile and Easy to Use – 3M heat shrink terminals,

There is no applicable UL or CSA standard for high

“C”

Width

“W”

Barrel I.D.

Length

Stud Size

Length

“L”

Barrel

“E”

Maximum Insulation

Diameter