DP-125 GRAY 1.7 FL OZ 3M, DP-125 GRAY 1.7 FL OZ Datasheet - Page 5

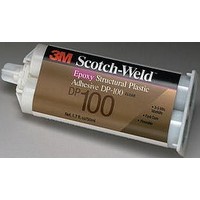

DP-125 GRAY 1.7 FL OZ

Manufacturer Part Number

DP-125 GRAY 1.7 FL OZ

Description

EPOXY 2 PART ADH DUAL CART 1.7FL.OZ

Manufacturer

3M

Series

Scotch Weldr

Datasheet

1.DP-125_GRAY_1.7_FL_OZ.pdf

(7 pages)

Specifications of DP-125 GRAY 1.7 FL OZ

Adhesive Type

Epoxy - 2 Part

Adhesive Applications

Bonding - General Purpose

Color

Gray

Dispensing Method

Dual-Cartridge

Volume

1.7fl.oz. (US)

Pack Quantity

2

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

3M

Epoxy Adhesives

DP125 Translucent and Gray

Handling/Curing

Information

3M™ EPX™

Pneumatic Applicator

Delivery Rates

™

Scotch-Weld

Directions For Use

1. For high strength structural bonds, paints, oxide films, oils, dust, mold release agents

2. Use gloves to minimize skin contact. Do not use solvents for cleaning hands.

3. Mixing.

4. For maximum bond strength, apply adhesive evenly to both surfaces to be joined.

5. Application to the substrates should be made within 20 minutes. Larger quantities

6. Join the adhesive coated surfaces and allow to cure at 60°F (16°C) or above until

7. Keep parts from moving during cure. Contact pressure necessary. Maximum shear

8. Excess uncured adhesive can be cleaned up with ketone type solvents.*

*Note: When using solvents, extinguish all ignition sources, including pilot lights, and

Adhesive Coverage (typical): A 0.005 in. thick bondline will yield a coverage of

50 ml Applicator – Maximum Pressure 50 psi

*Tests were run at a temperature of 70°F ± 2°F (21°C ± 1°C) and at maximum applicator pressure.

Adhesive*

3M™ Scotch-Weld™ Epoxy Adhesive DP125 Translucent

3M™ Scotch-Weld™ Epoxy Adhesive DP125 Gray

and all other surface contaminants must be completely removed. However, the

amount of surface preparation directly depends on the required bond strength and

the environmental aging resistance desired by user. For specific surface preparations

on common substrates, see the section on surface preparation.

For Duo Pak Cartridges

3M™ Scotch-Weld™ Epoxy Adhesives DP125 Translucent and Gray are supplied

in a dual syringe plastic duo-pak cartridge as part of the 3M™ EPX™ Applicator

System. To use, simply insert the duo-pak cartridge into the EPX applicator and start

the plunger into the cylinders using light pressure on the trigger. Next, remove the duo-

pak cartridge cap and expel a small amount of adhesive to be sure both sides of the

duo-pak cartridge are flowing evenly and freely. If automatic mixing of Part A and

Part B is desired, attach the EPX applicator mixing nozzle to the duo-pak cartridge

and begin dispensing the adhesive. For hand mixing, expel the desired amount of

adhesive and mix thoroughly. Mix approximately 15 seconds after uniform color is

obtained.

For Bulk Containers

Mix thoroughly by weight or volume in the proportions specified in the typical

uncured properties section. Mix approximately 15 seconds after uniform color is

obtained.

and/or higher temperatures will reduce this working time.

completely firm. Heat up to 200°F (93°C), will speed curing. These products will

cure in 7 days @ 75°F (24°C).

strength is obtained with a 3-5 mil bond line.

™

follow manufacturer’s precautions and directions for use.

- 5 -

320 sq. ft./gallon.

1/4 in. Nozzle

gms/minute

63.6

26.4