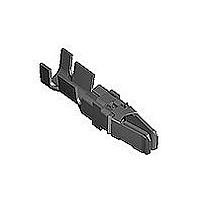

66741-8 TE Connectivity, 66741-8 Datasheet

66741-8

Specifications of 66741-8

Related parts for 66741-8

66741-8 Summary of contents

Page 1

... Figure 1. All tests are performed at ambient environmental conditions per Test Specification 109-1 unless otherwise specified. ©2011 Tyco Electronics Corporation, | Indicates Change a TE Connectivity Ltd. Company *Trademark All Rights Reserved TE logo is a trademark. For latest revision, visit out website at www.te.com/documents For Regional Customer service, visit our website at www ...

Page 2

Test Requirements and Procedures Summary Test Description Examination of Product Termination Resistance, Specified Current Termination Resistance, Dry Circuit Current Cycling Vibration Physical Shock Engaging Force Separation Force Rev A Requirement Meets requirements of product drawing and applicable TE application ...

Page 3

Test Description Crimp Tensile Durability Humidity-Temperature Cycling Mixed Flowing Gas Temperature Life Shall meet visual requirements, show no physical damage, and shall meet NOTE requirements of additional tests as specified in the Test Sequence in Figure 2. Rev A Requirement ...

Page 4

Product Qualification and Requalification Test Sequence Test or Examination Examination of Product Termination Resistance, Specified Current Termination Resistance, Dry Circuit Current Cycling Temperature Rise vs Current Vibration Physical Shock Engagement Force Separation Force Durability Crimp Tensile Humidity-Temperature Cycling (e) ...

Page 5

Quality Conformance Inspection The applicable quality inspection plan will specify the sampling acceptable quality level to be used. Dimensional and functional requirements shall be in accordance with the applicable product drawing and this specification. Termination Resistance Measurement Points Cable ...

Page 6

Rev A Gage .0000 1 .110 .250 ± .020 - .0001 + .0000 2 .100 .250 ± .020 - .0001 Figure 5 Engagement and Separating Gages 108-10037 ...