ADDAC85D-CBI-V Analog Devices Inc, ADDAC85D-CBI-V Datasheet - Page 8

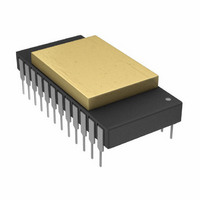

ADDAC85D-CBI-V

Manufacturer Part Number

ADDAC85D-CBI-V

Description

IC DAC 12BIT LOW COST 24-CDIP

Manufacturer

Analog Devices Inc

Datasheet

1.ADDAC80NZ-CBI-V.pdf

(16 pages)

Specifications of ADDAC85D-CBI-V

Rohs Status

RoHS non-compliant

Settling Time

2µs

Number Of Bits

12

Data Interface

Parallel

Number Of Converters

1

Voltage Supply Source

Dual ±

Power Dissipation (max)

300mW

Operating Temperature

0°C ~ 70°C

Mounting Type

Through Hole

Package / Case

24-CDIP (0.600", 15.24mm)

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

ADDAC85D-CBI-V

Manufacturer:

a

Quantity:

32

ADDAC80/ADDAC85/ADDAC87

ACCURACY

Accuracy error of a D/A converter is the difference between the

analog output that is expected when a given digital code is

applied and the output that is actually measured with that code

applied to the converter. Accuracy error can be caused by gain

error, zero error, linearity error, or any combination of the three.

Of these three specifications, the linearity error specification is

the most important since it cannot be corrected. Linearity error

is specified over its entire temperature range. This means that

the analog output will not vary by more than its maximum

specification, from an ideal straight line drawn between the

end points (inputs all “1”s and all “0”s) over the specified

temperature range.

Differential linearity error of a D/A converter is the deviation

from an ideal 1 LSB voltage change from one adjacent output

state to the next. A differential linearity error specification of

± 1/2 LSB means that the output voltage step sizes can range

from 1/2 LSB to 1 1/2 LSB when the input changes from one

adjacent input state to the next.

DRIFT

Gain Drift

A measure of the change in the full scale range output over

temperature expressed in parts per million of full scale range

per °C (ppm of FSR/°C). Gain drift is established by: 1) testing

the end point differences for each ADDAC80 model at the

lowest operating temperature, 25°C and the highest operating

temperature; 2) calculating the gain error with respect to the

25°C value and; 3) dividing by the temperature change.

Offset Drift

A measure of the actual change in output with all “1”s on the

input over the specified temperature range. The maximum

change in offset is referenced to the offset at 25°C and is

divided by the temperature range. This drift is expressed in

parts per million of full scale range per °C (ppm of FSR/°C).

SETTLING TIME

Settling time for each model is the total time (including slew

time) required for the output to settle within an error band

around its final value after a change in input.

Voltage Output Models

Three settling times are specified to 0.01% of full scale range

(FSR); two for maximum full scale range changes of 20 V, 10 V

and one for a 1 LSB change. The 1 LSB change is measured at

the major carry (0 1 1 1 . . . 1 1 to 1 0 0 0 . . . 0 0), the point at

which the worst case settling time occurs. The settling time

characteristic depends on the compensation capacitor selected,

the optimum value is 25 pF as shown in Figure 3a.

Current Output Models

Two settling times are specified to ± 0.01% of FSR. Each is given

for current models connected with two different resistive loads:

10 Ω to 100 Ω and 1000 Ω to 1875 Ω. Internal resistors are provided

for connecting nominal load resistances of approximately 1000 Ω

to 1800 Ω for output voltage ranges of ±1 V and 0 V to –2 V.

POWER SUPPLY SENSITIVITY

Power supply sensitivity is a measure of the effect of a power

supply change on the D/A converter output. It is defined as a

percent of FSR per percent of change in either the positive or

negative supplies about the nominal power supply voltages.

REFERENCE SUPPLY

All models are supplied with an internal 6.3 V reference voltage

supply. This voltage (Pin 24) is accurate to ± 1% and must be

connected to the Reference Input (Pin 16) for specified opera-

tion. This reference may also be used externally with external

current drain limited to 2.5 mA. An external buffer amplifier is

recommended if this reference is to be used to drive other sys-

tem components. Otherwise, variations in the load driven by the

reference will result in gain variations. All gain adjustments

should be made under constant load conditions.

ANALYZING DEVICE ACCURACY OVER THE

TEMPERATURE RANGE

For the purposes of temperature drift analysis, the major device

components are shown in Figure 4. The reference element and

buffer amplifier drifts are combined to give the total reference

temperature coefficient. The input reference current to the

DAC, I

show the same drift rate as the reference voltage. The DAC

output current, I

codes, is designed to track I

these currents over temperature, it will contribute to the gain

T.C. The bipolar offset resistor, R

R

system drift errors. The input offset voltage drift of the output

amplifier, OA, also contributes a small error.

GAIN

, also have temperature coefficients that contribute to

REF

1–12

, is developed from the internal reference and will

DATA

IN

100

0%

90

10

JUNCTION

SUMMING

DAC

10V

>1mV

, which is a function of the digital input

20

18

25pF

C

V

REF

5V

5V

OUT

F

; if there is a slight mismatch in

15

BP

, and gain setting resistor,

100pF

500ns

2k

TEKTRONIX

7A13

HP6216A

10V