1-917484-5 TE Connectivity, 1-917484-5 Datasheet - Page 6

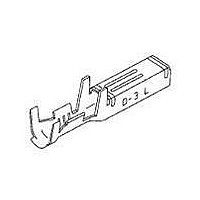

1-917484-5

Manufacturer Part Number

1-917484-5

Description

DYNAMIC D-3 REC CONT. 2L 16-14

Manufacturer

TE Connectivity

Series

D3 Seriesr

Specifications of 1-917484-5

Product Type

Contacts

Contact Gender

Socket (Female)

Mounting Style

Wire

Termination Style

Crimp

Wire Gauge Range

16-14

Contact Material

Copper Alloy

Wire Size (awg)

16-14

Product Series

D-3

Insulation Diameter (mm [in])

2.20-2.80 [.086-.110]

Insertion Force

High

Termination End Plating

Tin

Wire Range (mm [awg])

1.25-2.00² [16-14]

Contact Type

Socket

Contact Plating, Mating Area, Material

Tin

Contact Base Material

Copper Alloy

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Wire Range Mark

2L

Applies To

Wire/Cable

Packaging Quantity

3,000

Packaging Method

Reel

Lead Free Status / Rohs Status

Details

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

1-917484-5

Manufacturer:

TE

Quantity:

20 000

3.5.12 耐久性

3.5.12 Durability

3.5.13 ハウジング ・ ロック強度

3.5.13 Housing Locking Strength

3.5.14 はんだ付け性

3.5.14 Solderability

Rev. J5

Para.

項目

Test Items

試験項目

試験後、総合抵抗(ローレベル)

の条件に合致すること。

Termination Resistance

(Low Level).

シリーズ名

D-3100S

D-3200S

D-3230

D-3100D

D-3200D

D-3400

D-3500

Series

D-3100S

D-3200S

D-3230

D-3100D

D-3200D

D-3400

D-3500

試験面は新鮮なはんだ面が、95

% 以上であること。

Wet Solder Coverage :

95 % Min.

Product Specification

規

Requirements

Fig.3 (続く)

Fig.3 (CONT.)

格

製品規格

ロック強度

Strength

N(min)

N 以上

値

39.2

39.2

147

147

196

147

147

196

98

98

98

98

98

98

毎分 100mmの割合で、コネクタ・アセンブ

リを下記のサイクルで挿入・引抜を繰り返

す。

EIA364-9

100回 : 錫めっき

500回 : 金めっき

Repeat Insertion/extruction of

connector assembly following times at

100mm/min.operation speed.

EIA364-9

100 times : Tin-Plating

500 times : Gold-Plating

ハウジングのロック強度を測定

EIA364-98

Measure Housing locking strength.

EIA364-98

はんだ温度 : 235 ± 5 °C

はんだ浸漬時間 : 5 ± 0.5 s.

EIA364-52

MIL-STD-202 試験法208

Solder Temperature : 235±5℃

Immersion Duration : 5 ± 0.5 s.

EIA364-52

MIL-STD-202 Method 208

試

Procedures

験

方

法

108-5349

6 of 12