170362-1 TE Connectivity, 170362-1 Datasheet - Page 5

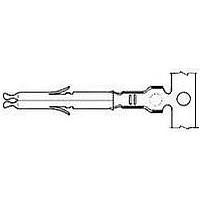

170362-1

Manufacturer Part Number

170362-1

Description

UNIV M-N-L SOC. 22-18 AWG

Manufacturer

TE Connectivity

Specifications of 170362-1

Product Type

Contacts

Contact Gender

Socket (Female)

Voltage Rating

600 V

Current Rating

9.5 A

Mounting Style

Snap In

Termination Style

Quick Connect

Contact Plating

Pre Tin

Contact Material

Brass

Wire Gauge Range

22-18

Connector Line

Mini-Universal MATE-N-LOK

Wire Insulation Diameter (mm [in])

1.50 – 2.40 [0.059 – 0.094], 3.38 [0.133]

Voltage (vac)

600

Current Rating (a)

9.5

Termination Method

Crimp

Solder Tail Contact Plating

Pre-Tin

Wire Range (mm [awg])

0.30-0.90² [22-18], (2) 0.30-0.40² [(2) 22]

Contact Diameter (mm [in])

0.99 [0.039]

Stock Thickness (mm [in])

0.25 [0.010]

Contact Type

Socket

Contact Termination Type

Crimp

Contact Base Material

Brass

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Applies To

Wire/Cable

Packaging Method

Strip

Lead Free Status / Rohs Status

Details

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

170362-1

Manufacturer:

TE

Quantity:

108 000

Company:

Part Number:

170362-1

Manufacturer:

TE

Quantity:

45 000

Part Number:

170362-1

Manufacturer:

TE/泰科

Quantity:

20 000

3.5.17

3.5.18

3.5.19

3.5.20

3.5.21

3.5.22

3.5.23

3.5.24

3.5.25

Rev G

Humidity-

Temperature Cycling

Humidity, Steady

State

Salt Spray

Temperature Life

Resistance to Cold

Ammonia Gas

Resistivity

Sulfurous Acid Gas

Resistivity

Hydrogen Sulfide Gas

Resistivity

Chemical Solvent

Resistivity

Insulation resistance:

100 M M in.(Final)

Termination resistance:

60 m M in.(Final)

Insulation resistance:

100 M M in.(Final)

Termination resistance:

60 m M in.(Final)

TR: 60 m M ax. (Final)

TR: 60 m M ax. (Final)

TR: 60 m M ax. (Final)

Tested sample shall show no

evidence of abnormalities in

appearance.

TR: 60 m M ax. (Final)

Tested sample shall show no

evidence of abnormalities in

appearance.

TR: 60 m M ax. (Final)

Tested sample shall show no

evidence of abnormalities in

appearance.

TR: 60 m M ax. (Final)

Connector shall be free from

fusion and discoloration that are

detrimental to connector

functions.

Figure 1 (End)

Subject mated connectors to

humidity-temperature

changes between +25°C and

+65°C at 95%R.H.

Tyco Spec 109-23-3, Method

III, Condition B.

Subject mated connectors to

90~95%R.H., 40°C for

500 cycles. Tyco Spec 109-

23-2, Method II.

Subject mated connectors to

5 % salt concentration for 48

hours at 35±2°C. Tyco Spec

109-24, Condition B.

Subject mated connectors to

85± 2 °C, 500 hours.

Tyco Spec 109-43/ EIA 364-

17A.

Subject mated connectors to

-40±3°C, 96 hours.

Subject mated connectors to

ammonia gas atmosphere,

generated from 400g of 28%

ammonia solution in a

desiccator in a closed

chamber for 40 mins.

Temperature in the

desiccator: room

temperature.

Subject mated connectors to

atmosphere of 10±3 ppm

SO

RH Min. for 96 hours.

Subject mated connectors to

hydrogen sulfide gas

atmosphere of 3 ppm H

concentration for 96 hours.

Immerse sample connector

in chemical solvent

(trichlorethane or isopropyl

alcohol) kept at ambient

temperature for 2 mins.

2

concentration at 90%

2

S

108-51021

5 of 10