AD2S81AJD Analog Devices Inc, AD2S81AJD Datasheet - Page 13

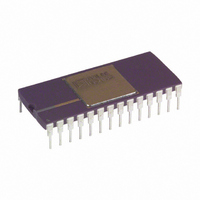

AD2S81AJD

Manufacturer Part Number

AD2S81AJD

Description

IC R/D CONV TRACKING 28CDIP

Manufacturer

Analog Devices Inc

Type

R/D Converterr

Datasheet

1.AD2S80AJD.pdf

(16 pages)

Specifications of AD2S81AJD

Rohs Status

RoHS non-compliant

Input Type

Parallel

Output Type

Digital

Interface

Parallel

Current - Supply

30mA

Mounting Type

Through Hole

Package / Case

28-CDIP (0.600", 15.24mm)

Resolution (bits)

12bit

Input Channel Type

Parallel

Data Interface

Parallel

Supply Voltage Range - Analog

± 10.8V To ± 13.2V

Supply Current

19mA

Digital Ic Case Style

DIP

No. Of Pins

40

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

1

SOURCES OF ERRORS

Integrator Offset

Additional inaccuracies in the conversion of the resolver signals

will result from an offset at the input to the integrator as it will

be treated as an error signal. This error will typically be 1 arc

minute over the operating temperature range.

A description of how to adjust from zero offset is given in the

section “COMPONENT SELECTION” and the circuit required

is shown in Figure 1.

Differential Phase Shift

Phase shift between the sine and cosine signals from the resolver

is known as differential phase shift and can cause static error.

Some differential phase shift will be present on all resolvers as a

result of coupling. A small resolver residual voltage (quadrature

voltage) indicates a small differential phase shift. Additional phase

shift can be introduced if the sine channel wires and the cosine

channel wires are treated differently. For instance, different cable

lengths or different loads could cause differential phase shift.

The additional error caused by differential phase shift on the

input signals approximates to

where a = differential phase shift (degrees).

This error can be minimized by choosing a resolver with a small

residual voltage, ensuring that the sine and cosine signals are

handled identically and removing the reference phase shift (see

section “CONNECTING THE RESOLVER”). By taking these

precautions the extra error can be made insignificant.

Under static operating conditions phase shift between the refer-

ence and the signal lines alone will not theoretically affect the

converter’s static accuracy.

However, most resolvers exhibit a phase shift between the signal

and the reference. This phase shift will give rise under dynamic

conditions to an additional error defined by:

For example, for a phase shift of 20 degrees, a shaft rotation of

22 rps and a reference frequency of 5 kHz, the converter will

exhibit an additional error of:

This effect can be eliminated by placing a phase shift in the

reference to the converter equivalent to the phase shift in the

resolver (see section “CONNECTING THE RESOLVER”).

Note: Capacitive and inductive crosstalk in the signal and reference

leads and wiring can cause similar problems.

Reversion error, or side-to-side nonlinearity, is a result of differences in the

up and down rates of the VCO.

b = signal to reference phase shift (degrees).

Shaft Speed (rps) × Phase Shift (Degrees )

Error = 0.53 a × b arc minutes

22 × 20

Reference Frequency

5000

0.088 Degrees

VELOCITY ERRORS

The signal at the INTEGRATOR OUTPUT pin relative to the

ANALOG GROUND pin is an analog voltage proportional to

the rate of change of the input angle. This signal can be used to

stabilize servo loops or in the place of a velocity transducer.

Although the conversion loop of the AD2S80A includes a digital

section there is an additional analog feedback loop around the

velocity signal. This ensures against flicker in the digital posi-

tional output in both dynamic and static states.

A better quality velocity signal will be achieved if the following

points are considered:

1. Protection.

2. Reversion error.

3. Ripple and Noise.

Following the preceding precautions will allow the user to use

the velocity signal in very noisy environments, for example,

PWM motor drive applications. Resolver/converter error curves

may exhibit apparent acceleration/deceleration at a constant

velocity. This results in ripple on the velocity signal of frequency

twice the input rotation.

The velocity signal should be buffered before use.

The reversion error can be nulled by varying one supply rail

relative to the other.

Noise on the input signals to the converter is the major cause of

noise on the velocity signal. This can be reduced to a minimum

if the following precautions are taken:

The resolver is connected to the converter using separate

twisted pair cable for the sine, cosine and reference signals.

Care is taken to reduce the external noise wherever possible.

An HF filter is fltted before the Phase Sensitive Demodulator

(as described in the section HF FILTER).

A resolver is chosen that has low residual voltage, i.e., a small

signal in quadrature with the reference.

Components are selected to operate the AD2S80A with the

lowest acceptable bandwidth.

Feedthrough of the reference frequency should be removed by

a filter on the velocity signal.

Maintenance of the input signal voltages at 2 V rms will

prevent LSB flicker at the positional output. The analog

feedback or hysteresis employed around the VCO and the

intergrator is a function of the input signal levels (see sec-

tion “INTEGRATOR”) .

1

AD2S80A