LMD18245T/NOPB National Semiconductor, LMD18245T/NOPB Datasheet - Page 13

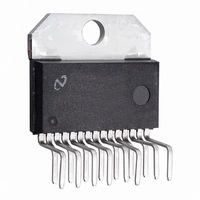

LMD18245T/NOPB

Manufacturer Part Number

LMD18245T/NOPB

Description

IC H BRIDGE 3A 55V TO-220

Manufacturer

National Semiconductor

Datasheet

1.LMD18245TNOPB.pdf

(21 pages)

Specifications of LMD18245T/NOPB

Applications

DC Motor Driver, Stepper Motor Driver, H Bridge

Number Of Outputs

1

Current - Output

3A

Voltage - Supply

12 V ~ 55 V

Operating Temperature

-40°C ~ 125°C

Mounting Type

Through Hole

Package / Case

TO-220-15 (Bent and Staggered Leads)

Operating Temperature Classification

Automotive

Package Type

TO-220

Operating Supply Voltage (min)

12V

Operating Supply Voltage (max)

55V

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Voltage - Load

-

Lead Free Status / Rohs Status

Compliant

Other names

*LMD18245T

*LMD18245T/NOPB

LMD18245T

*LMD18245T/NOPB

LMD18245T

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

LMD18245T/NOPB

Manufacturer:

ST

Quantity:

14 300

Part Number:

LMD18245T/NOPB

Manufacturer:

NS/国半

Quantity:

20 000

The Typical Application

Figure 7 shows the typical application, the power stage of a

chopper drive for bipolar stepper motors. The 20 k

and 2.2 nF capacitor connected between RC and ground set

the off-time at about 48 µs, and the 20 k resistor connected

between CS OUT and ground sets the gain at about 200 mA

ONE-PHASE-ON FULL STEP DRIVE (WAVE DRIVE)

To make the motor take full steps, windings A and B can be

energized in the sequence

where A represents winding A energized with current in one

direction and A* represents winding A energized with current

in the opposite direction. The motor takes one full step each

time one winding is de-energized and the other is energized.

To make the motor step in the opposite direction, the order of

A B A* B* A

FIGURE 7. Typical Application Circuit for Driving Bipolar Stepper Motors

…,

resistor

13

per volt of the threshold for chopping. Digital signals control

the thresholds for chopping, the directions of the winding

currents, and, by extension, the drive type (full step, half

step, etc.). A µprocessor or µcontroller usually provides the

digital control signals.

the above sequence must be reversed. Figure 8 shows the

winding currents and digital control signals for a wave drive

application of the typical application circuit.

TWO-PHASE-ON FULL STEP DRIVE

To make the motor take full steps, windings A and B can also

be energized in the sequence

and because both windings are energized at all times, this

sequence produces more torque than that produced with

AB A*B A*B* AB* AB

…,

www.national.com

01187816