BL-22F0-0132 LIGHTING SCIENCE GROUP CORPORATION, BL-22F0-0132 Datasheet - Page 2

BL-22F0-0132

Manufacturer Part Number

BL-22F0-0132

Description

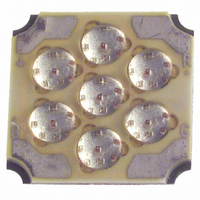

LED ARRAY RD/GRN/BLU .56X.56 SMD

Manufacturer

LIGHTING SCIENCE GROUP CORPORATION

Datasheet

1.BL-22F0-0132.pdf

(4 pages)

Specifications of BL-22F0-0132

Color

Amber

Current - Test

630mA Red, 630mA Green, 210mA Blue

Luminous Flux @ Current - Test

59lm Red, 31lm Green, 4.2lm Blue

Current - Max

630mA Red, 630mA Green, 210mA Blue

Lumens @ Current - Max

59lm Red, 31lm Green, 4lm Blue

Lumens/watt @ Current - Test

31lm/W Red, 12lm/W Green, 5lm/W Blue

Voltage - Forward (vf) Typ

3V Red, 4V Blue, 4V Green

Wavelength

630nm, 523nm, 470nm

Lens Style/size

Square, 14.1mm

Viewing Angle

120°

Mounting Type

Surface Mount

Package / Case

0.56" L x 0.56" W x 0.1" H (14.1mm x 14.1mm x 2.54mm)

Illumination Color

RGB

Power Consumption

1.5 W

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Other names

521-1002

laminaceramics.com

To see how you can realize all these design benefits, to request a sample, or to speak with an engineer

about your design, contact Lamina Ceramics at 800.808.LTCC (5822) or visit laminaceramics.com.

Mechanical Specifications

Lamina Ceramics, 120 Hancock Lane, Westampton, NJ 08060

1-800-808-LTCC (5822) www.laminaceramics.com

1

4

0.570 [14.48]

0.555 [14.10]

APPLY (V+)

VOLTAGE HERE

RED

APPLY (V-)

VOLTAGE HERE

SQ

SQ

3

2

4

1

2

3

VOLTAGE HERE

VOLTAGE HERE

APPLY (V+)

APPLY (V+)

GREEN

BLUE

0.100 [2.54] MAX

4X MOUNTING HOLE

FOR 2-56 SCREW

Notes

O

R

Lamina's BL Series Light

Engines project a Lambertain

radiation pattern, with

projection angles built into

the package cavity at

approximately 150º. It will be

necessary for users to create

an optical reflector and lens

structure that meet their light

dispersion requirements.

Please contact Lamina

Application Engineering for

support with your optical

needs.

H

R

Lamina's BL Series Light

Engines are created with a

heat spreader fabricated into

the ceramic package. This

heat spreader provides the

most efficient thermal path

from the die junction to the

heat sink. The operational

die junction temperature

must not be allowed to

exceed 125ºC and should

ideally be maintained as

close to 25ºC as possible.

With increasing power levels,

die junction temperature will

rise and light output

efficiency will drop. These

variables must be taken into

consideration when selecting

a light engine for your

application. Please contact

Lamina Application

Engineering for support with

your thermal management

needs.

PTICAL

ECOMMENDATIONS

EAT

ECOMMENDATIONS

S

INK