MCP6V01RD-TCPL Microchip Technology, MCP6V01RD-TCPL Datasheet - Page 25

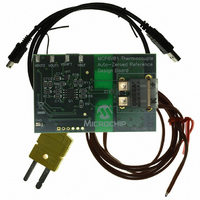

MCP6V01RD-TCPL

Manufacturer Part Number

MCP6V01RD-TCPL

Description

REF DESIGN THERMCPL FOR MCP6V01

Manufacturer

Microchip Technology

Datasheets

1.MCP6V01RD-TCPL.pdf

(44 pages)

2.MCP6V01RD-TCPL.pdf

(30 pages)

3.MCP6V03-ESN.pdf

(40 pages)

Specifications of MCP6V01RD-TCPL

Channels Per Ic

1 - Single

Amplifier Type

Chopper (Zero-Drift)

Output Type

Rail-to-Rail

Slew Rate

0.5 V/µs

Current - Output / Channel

22mA

Operating Temperature

-40°C ~ 125°C

Voltage - Supply, Single/dual (±)

1.8 V ~ 5.5 V

Board Type

Fully Populated

Utilized Ic / Part

MCP6V01

Silicon Manufacturer

Microchip

Silicon Core Number

MCP6V01

Kit Application Type

Sensing - Temperature

Application Sub Type

Temperature Sensor

Processor To Be Evaluated

MCP6V01

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

-3db Bandwidth

-

Current - Supply (main Ic)

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

4.3.8.4

The dual op amp amplifiers shown in

Figure 4-15

greater than 1, and a common mode gain of 1 .They

can use the layout shown in

ting resistors (R

bined so that the thermal voltages can be canceled.

The guard traces (with ground vias at the ends) help

minimize the thermal gradients. The resistor layout

cancels the resistor thermal voltages, assuming the

temperature gradient is constant in the region of the

resistors:

EQUATION 4-4:

FIGURE 4-11:

for Dual Non-inverting Amplifier.

© 2008 Microchip Technology Inc.

Where:

Thermal voltages are approximately equal

Note:

G

G

DM

CM

V

V

IA

IB

R1

R2

R3

=

=

Changing the orientation of the resistors

will usually cause a significant decrease in

the cancellation of the thermal voltages.

(V

(V

produce a non-inverting difference gain

Dual Non-inverting Amplifier Layout

for Thermo-junctions

½ MCP6V02

½ MCP6V02

OA

OA

1 + R

1, common mode gain

V

2

) between the two sides are not com-

OS

– V

+ V

is neglected

3

OB

V

OB

R

R

R

R

/R

OA

PCB Layout and Schematic

1

1

V

2

2

) ≈ (V

)/2 ≈ (V

2

U1

U

U

IA

, differential mode gain

1

1

V

V

Figure

IA

IB

OB

IA

R

R

– V

3

3

+ V

IB

4-11. The gain set-

)G

IB

Figure 4-14

)/2

DM

R1

R2

R3

V

V

OA

OB

and

4.3.8.5

In cases where an individual resistor needs to have its

thermo-junction voltage cancelled, it can be split into

two equal resistors as shown in

the thermal gradients near the resistors as small as

possible, the layouts are symmetrical with a ring of

metal around the outside. Make R

R

FIGURE 4-12:

Resistors.

Minimize temperature gradients at critical components

(resistors, op amps, heat sources, etc.):

• Minimize exposure to gradients

• Align with constant temperature (contour) lines

• Minimize magnitude of gradients

Make the temperature gradient point in one direction:

• Add guard traces

• Shape any FR4 gaps

2A

Note:

- Small components

- Tight spacing

- Shield from air currents

- Place on PCB center line

- Select parts with lower power dissipation

- Use same metal junctions on thermo-junc-

- Use metal junctions with low temperature to

- Large distance from heat sources

- Ground plane underneath (large area)

- FR4 gaps (no copper for thermal insulation)

- Series resistors inserted into traces (adds

- Use heat sinks

- Constant temperature curves follow the

- Connect to ground plane

- Constant temperature curves follow the

= R

tions that need to match

voltage coefficients

thermal and electrical resistance)

traces

edges

R

2B

1A

R

= 2R

1A

Changing the orientation of the resistors

will usually cause a significant decrease in

the cancellation of the thermal voltages.

Other PCB Thermal Design Tips

R

2

.

1B

R

MCP6V01/2/3

1B

PCB Layout for Individual

Figure

1A

R

R

DS22058B-page 25

2A

= R

2B

R

R

2A

2B

4-12. To keep

1B

= R

1

/2 and