CBC5300-24C Cymbet Corporation, CBC5300-24C Datasheet - Page 6

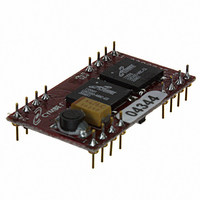

CBC5300-24C

Manufacturer Part Number

CBC5300-24C

Description

ENERCHIP EH CBC5300 MODULE

Manufacturer

Cymbet Corporation

Series

EnerChip™ EHr

Type

Energy Harvestingr

Datasheet

1.CBC5300-24C.pdf

(11 pages)

Specifications of CBC5300-24C

Module/board Type

Energy Harvesting Module

Input Voltage

0.25 V to 4 V

Output Voltage

3.6 V

Board Size

30.5 mm x 17.2 mm

Maximum Operating Temperature

+ 70 C

Minimum Operating Temperature

0 C

Product

Power Management Modules

Dimensions

30.5 mm x 17.2 mm

Lead Free Status / RoHS Status

Request inventory verification / Request inventory verification

For Use With/related Products

Thin Film Rechargeable Solid State Battery

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

859-1000-5

Preliminary

EnerChip EH CBC5300

Again, Vmin and Vmax are functions of the battery voltage and the circuit operating specifications. Battery

resistance varies according to temperature and state-of-charge as described above. Worst-case conditions

are often applied to the calculations to ensure proper system operation over temperature extremes, battery

condition, capacitance tolerance, etc.

The composite resistance of the 2-cell parallel EnerChip arrangement on the CBC5300 board ranges from

750Ω to about 1500Ω. At the output stage, a 1000µF, low resistance capacitor in parallel with the EnerChips

delivers peak power to the external circuit, which might contain a microcontroller and radio, for example. The

EnerChips deliver the lower level, continuous (average) power to the load. EnerChip electrical resistance is fairly

constant from 100% state-of-charge to about 10% state-of-charge; its internal resistance begins to increase

significantly only when the state-of-charge is reduced below approximately 10%.

A question often arises: “How many radio transmission pulses can be delivered by the two EnerChips on the

CBC5300?” The answer depends on a number of factors including the pulse current amplitude, pulse duration,

operating temperature, etc. The question will be addressed by way of example.

To extend the life of the EnerChips, assume the EnerChips will be cutoff from the load when a 50% state-

of-charge has been reached. (See the section titled Battery Protection for a description of how this is

accomplished.) With 100µAh of combined capacity in the two EnerChips, a 50% state-of-charge is simply

50µAh. Further, supppose each radio transmission uses 30mA for 20ms. The charge per pulse is:

30mA * 20ms = 600µA-seconds = 0.167µAh.

That amount of charge is transferred from the EnerChips into the output capacitor, which then delivers the

charge to the load at the rate demanded by the radio. On the CBC5300, there is a series diode between the

output capacitor and the output pin (V

), resulting in a diode voltage drop that must be taken into account.

OUT2

In that scenario, 50% of the 100µAh allows 50µAh / 0.167µAh = 300 transmissions to be made if no ambient

power is available (i.e., when CHARGE is high). In this example, the background (sleep) current that is drawn

between transmissions has been neglected. Use actual power consumption numbers to arrive at the number

of transmissions available in any given application. The MCU can be programmed to utilize this information to

conserve power and maximize the service life of the EnerChips, as described in the following sections.

Battery Protection

The CBC5300 energy harvester module contains a low battery cutoff circuit that prevents the EnerChips from

being completely discharged - a condition that would permanently damage the battery. The cutoff circuit

places a parasitic 800nA load on the battery - a load that would discharge the two EnerChips in approximately

125 hours, or just over 5 days. If the EnerChips are allowed to reach the cutoff voltage at such low discharge

currents, their specified cycle life will be reached after a few hundred of such deep discharge cycles. To

avoid this condition and extend the service life of the EnerChip, it is advisable to program the MCU to count

transmission cycles or elapsed time to determine when the EnerChips’ state-of-charge is approximately 50%,

at which time the MCU would force itself or another system circuit element to briefly draw high power from the

CBC5300, forcing the CBC5300 circuit into a cutoff mode and thereby disconnecting the EnerChips from the

circuit. Drawing a brief burst of a few milli-Amperes from the CBC5300 will force the cutoff condition to occur

within a few seconds. This will ensure that the charge/discharge cycle life of the EnerChips will be greater than

5000, as rated. To calculate the number of hours the EnerChips are capable of supplying energy to the load,

add the cutoff current to the average load current drawn by the system and divide the sum into the combined

100µAh capacity of the two EnerChips. The quotient is the number of hours until the EnerChip is totally

depleted. Divide that number in half to reach the 50% depth-of-discharge time.

Guidelines for Attaching Energy Harvesting Transducers

Energy harvesting transducers (e.g., inductive, piezoelectric, thermoelectric) may be attached to the CBC5300.

©2009 Cymbet Corporation • Tel: +1-763-633-1780 • www.cymbet.com

DS-72-06 Rev06

Page 6 of 11