MDEV-LICAL-MS Linx Technologies Inc, MDEV-LICAL-MS Datasheet - Page 3

MDEV-LICAL-MS

Manufacturer Part Number

MDEV-LICAL-MS

Description

DEV SYSTEM MS SERIES 418MHZ

Manufacturer

Linx Technologies Inc

Series

MSr

Type

Encoder, Decoderr

Datasheet

1.MDEV-LICAL-MS.pdf

(7 pages)

Specifications of MDEV-LICAL-MS

Supply Voltage (min)

7 V

Product

RF Development Tools

Supply Voltage (max)

16 V

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

For Use With/related Products

MS Series Encoder and Decoder

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

MDEV-LIC-MS

MDEV-LIC-MS

MDEV-LIC-MS

USING THE DEVELOPMENT BOARDS

TROUBLESHOOTING

THE PROTOTYPING AREA

Page 4

1. Press and hold the CREATE button on the encoder board to create a new Code

2. Once the CREATE button is released, the MODE_IND LED will begin to flash to

3. Press the LEARN button on the decoder board and the MODE_IND LED will

• Check the battery to make sure it is not dead.

• Make sure that the baud rate switches are set the same on both boards.

• Make sure that the antenna is connected.

• Check to see if the PDN switch is on, placing the encoder and decoder into

• Make sure that you set your Control Permissions correctly. If you have not set

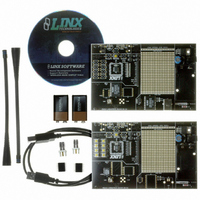

Use of the development boards is straightforward. After unpacking the

development system, attach an antenna to each board, install the supplied 9V

battery, and turn on the power switches. The encoder and decoder will have

default settings from the factory and will work straight out of the box. To create

a new address, follow these steps:

If the boards fail to work out of the box, then try the following:

If all of these appear to be in order, then you can call 800-736-6677 or email

techsupport@linxtechnologies.com for technical support.

The prototyping area is the same on both boards and contains a large area of

plated through holes so that external circuitry can be placed on the board. This

circuitry can be interfaced with the MS encoder or decoder through the breakout

header to the right. At the bottom of this area is a row connected to the 3V power

supply and at the top is a row connected to ground.

All of the data lines are connected to a wire-wrap header to the right, allowing

easy access from the prototyping area. The DATA_IN, DATA_OUT and TX_ID

lines are also available on the header, as well as the PDN lines from the RF

modules. This allows complete control of the entire system from the prototyping

area, giving the designer a great deal of flexibility in using the boards.

Word. The Code Word will be randomized for as long as the button is held down.

Once comfortable that the number is sufficiently random, release the button.

indicate that it is ready to accept Control Permissions. Press all of the data line

buttons that are to be recognized, then press the CREATE button again.

start flashing. Press any of the data line buttons on the encoder board and press

the LEARN button again. The encoder’s Code Word has been learned by the

decoder and they will now operate together.

Power Down Mode. In most cases the encoder PDN switch should be on.

the encoder to use a particular line, then when you press a button on the

encoder board, the MODE_IND LED on the decoder board will light up, but the

data line LED will not light up.

THE POWER SUPPLY

THE ENCODER BOARD

Figure 3: The Encoder Area

The Encoder Area

The power supply is the same on both boards and consists of a standard 9V

battery and a power jack connected to a 3.0V voltage regulator. The regulator

can provide approximately 500mA of current to the prototyping area. If the added

circuitry will need more than this, then the designer must add an external supply.

If the circuit will consistently draw more than 100mA of current, it might be better

to use the power jack, as the battery may run down fairly quickly, reducing testing

and development time.

The jack accepts a standard 5.5mm plug with the tip ground and the outer shell

7 to 16VDC positive supply. A reverse voltage protection diode has been

included on the board to protect the circuitry in case the voltage on the plug is

reversed, but it is still a good idea to double-check the polarity.

The encoder board has two sections that are of primary interest: the encoder

area and the transmitter area.

The figure below shows the encoder area of the development board.

The encoder is placed in the center beneath the Linx logo. To the right are

buttons that will pull the encoder data lines high when pressed. Button S0

corresponds to data line D0, S1 to D1 and so forth.

The diodes to the left isolate the data lines from each other while allowing any

line to activate the SEND line.

Beneath the encoder are two LEDs. D12 is connected to the MODE_IND line

and will light up as described in the MS Encoder Data Guide. D8 is connected to

the TX_CNTL line and will provide visual feedback by lighting up when the

encoder sends a word.

Page 5