TGA2514 TriQuint, TGA2514 Datasheet - Page 9

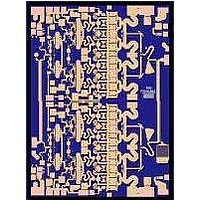

TGA2514

Manufacturer Part Number

TGA2514

Description

RF Amplifier Ku-Band 6.5W HPA

Manufacturer

TriQuint

Type

Power Amplifierr

Datasheet

1.TGA2514.pdf

(9 pages)

Specifications of TGA2514

Operating Frequency

13 GHz to 18 GHz

P1db

38 dBm

Operating Supply Voltage

9 V

Supply Current

4 A

Maximum Power Dissipation

20.8 W

Package / Case

2.87 mm x 3.9 mm

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

1023934

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

TGA2514

Manufacturer:

MAXIM

Quantity:

7 600

Company:

Part Number:

TGA2514

Manufacturer:

TriQuint Semiconductor

Quantity:

135

Company:

Part Number:

TGA2514-FL

Manufacturer:

TRIQUINT

Quantity:

500

Part Number:

TGA2514-FL

Manufacturer:

TRIQUINT

Quantity:

20 000

Company:

Part Number:

TGA2514N-FL

Manufacturer:

QORVO

Quantity:

265

Part Number:

TGA2514N-FL

Manufacturer:

TRIQUINT

Quantity:

20 000

GaAs MMIC devices are susceptible to damage from Electrostatic Discharge. Proper precautions should

be observed during handling, assembly and test.

TriQuint Semiconductor Texas Phone: (972)994-8465 Fax: (972)994 8504 Email: info-mmw@tqs.com Web: www.triquint.com

Reflow process assembly notes:

Component placement and adhesive attachment assembly notes:

Interconnect process assembly notes:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Use AuSn (80/20) solder with limited exposure to temperatures at or above 300°C

An alloy station or conveyor furnace with reducing atmosphere should be used.

No fluxes should be utilized.

Coefficient of thermal expansion matching is critical for long-term reliability.

Devices must be stored in a dry nitrogen atmosphere.

Vacuum pencils and/or vacuum collets are the preferred method of pick up.

Air bridges must be avoided during placement.

The force impact is critical during auto placement.

Organic attachment can be used in low-power applications.

Curing should be done in a convection oven; proper exhaust is a safety concern.

Microwave or radiant curing should not be used because of differential heating.

Coefficient of thermal expansion matching is critical.

Thermosonic ball bonding is the preferred interconnect technique.

Force, time, and ultrasonics are critical parameters.

Aluminum wire should not be used.

Discrete FET devices with small pad sizes should be bonded with 0.0007-inch wire.

Maximum stage temperature is 200°C.

(for 30 sec max).

Assembly Process Notes

Product Data Sheet

August 5, 2008

TGA2514

9