XA1E-BV413-RH-EMO IDEC, XA1E-BV413-RH-EMO Datasheet - Page 3

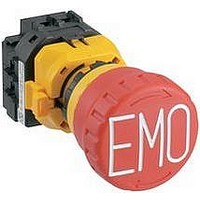

XA1E-BV413-RH-EMO

Manufacturer Part Number

XA1E-BV413-RH-EMO

Description

SWITCH, EMERGENCY STOP, 3NC/1NO, 250VAC

Manufacturer

IDEC

Datasheet

1.XA9Z-KG1.pdf

(8 pages)

Specifications of XA1E-BV413-RH-EMO

Contact Configuration

4PST-3NC / 1NO

Switch Operation

Pushlock Turn Reset

Contact Voltage Ac Nom

250V

Contact Voltage Dc Nom

250V

Contact Current Max

3A

Actuator Style

Mushroom

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

SEMI S2-compliant Combinations

Note: Numbers in the circle refer to the pictures of the corresponding control units shown above.

About SEMI

SEMI is an international industry association whose member companies produce materials, equipment, and related technology for

manufacturing semiconductor, flat panel display (FPD), and micro-electromechanical systems (MEMS) products. The SEMI safety

guideline was published for the semiconductor industry and it is observed with the same importance as standards.

SEMI S2-0706, 12.1 describes as follows; “The equipment should have an ‘emergency off’ (EMO) circuit. The EMO actuator (e.g.,

button), when activated, should place the equipment into a safe shutdown condition, without generating any additional hazard to per-

sonnel or the facility.” Because the semiconductor environment involves solvents and chemicals in many cases, some of which are

toxic, interrupting the power source may cause secondary accidents. SEMI safety guideline requires the installation of an emergency

off switch which disconnects only the part responsible for the hazardous situation, and maintains the functions of safety-related

devices (e.g., smoke detectors, gas/water leak detectors, pressure measurement devices, etc.).

Emergency off buttons should be located or guarded to minimize accidental activation (SEMI S2-0706, 12.5.1). The emergency off

button should be red and mushroom shaped. A yellow background for the EMO should be provided (SEMI S2-0706, 12.3).

XA9Z-KG1

The combination of IDEC’s EMO switch guards and emergency stop switches are approved

by TÜV Rheinland for compliance with SEMI S2 standards.

SEMI S2 Compliant Switches / Switch Guards

2

EMO Switch Guard

• Location of EMO switches on semiconductor manufacturing equipment

• No operation or regularly scheduled maintenance location should require

Acceptance criteria: controls should not be located above 1638 mm (64.5 in.) or

below 838 mm (33 in.) (SEMI S8-0705, 9.1.2).

more than 3 m (10 feet) travel to an EMO button (S2-0706, 12.5.2).

EMO button

HW9Z-KG3

HW9Z-KG4

XA9Z-KG1

1

XA9Z-KG1

XA Series

+

3

(3 m maximum)

10

15

1

4

: XA1E-BV4 ∗∗∗∗ -EMO;

: XW1E-BV4 ∗∗∗∗ -EMO;

: XW1E-BV4 ∗∗∗∗ -EMO;

: HW1E-BV4, HW1B-LV4;

HW9Z-KG3

Operator

7

4

HW9Z-KG3

XW Series

(3 m maximum)

+

2

11

5

8

: XA1E-BV3, XA1E-LV3;

16

: XW1E-BV4, XW1E-LV4, XW1E-TV4;

: XW1E-BV4, XW1E-LV4, XW1E-TV4;

: HW1B-X4;

5

EMO button

17

Applicable Emergency Stop Switches

: HW1B-Y2

9

HW9Z-KG4

XW Series

6

3

: XA1E-BV4, XA1E-LV4

+

HW9Z-KG4

14

6

12

: HW1B-V3;

10

: XW1E-BV5;

15

7

: HW1B-V4;

1638 mm

maximum

13

: HW1B-V3;

11

838 mm

minimum

16

8

: HW1B-X4;

14

: HW1B-V4;

12

The combination of EMO

switch and switch guard

can be used with the FB

series control boxes.

For details, see the FB

series control box catalog

(EP1132).

17

9

: HW1B-Y2

13

3