926681-3 TE Connectivity, 926681-3 Datasheet - Page 4

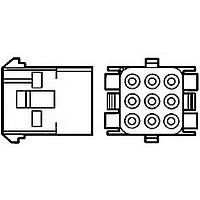

926681-3

Manufacturer Part Number

926681-3

Description

CAP, 12WAY

Manufacturer

TE Connectivity

Series

Universal Mate-N-Lokr

Datasheet

1.926647-3.pdf

(7 pages)

Specifications of 926681-3

Gender

Receptacle

No. Of Contacts

12

No. Of Rows

3

Pitch Spacing

6.35mm

Contact Gender

Socket

Connector Mounting

Free

Contact Material

Bronze

Approval Category

VDE, UL, CSA

Product Type

Connector

Product Line

Universal MATE-N-LOK

Connector Type

Housing

Mount

Free Hanging

Color

Natural

Mating Retention Type

Positive Lock

High Current

No

Current Rating (a)

19

Voltage (vac)

600

Row-to-row Spacing (mm [in])

6.35 [0.250]

Centerline (mm [in])

6.35 [0.250]

Number Of Positions

12

Mating Retention

With

Contact Diameter (mm [in])

2.13 [0.084]

Contact Type

Pin or Socket

Contact Layout

Matrix

Sealable

No

Connector Style

Receptacle

Housing Material

Polyamide - GF

Ul Flammability Rating

UL 94V-0

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

One Piece Housing

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

926681-3

Manufacturer:

TE Connectivity AMP Connectors

Quantity:

2 700

2.11.

2.12.

2.13.

2.14.

2.15.

2.16.

2.17.

2.18.

2.19.

Rev A

Contact Insertion Force - Test Group 6

The force required to insert each contact into its housing cavity was less than 22.2 N [5 lbf].

Contact Retention Force - Test Group 6

No physical damage occurred to either the contacts or the housing, and no contacts dislodged from the

housings as a result of supplying an axial load of 66.7 N [15 lbf] to standard contacts, and 111.2 N [25

lbf] to high retention contacts.

Crimp Tensile - Test Group 5

All crimp tensile values were greater than shown in Figure 3.

Durability - Test Group 2

No physical damage occurred as a result of manually mating and unmating the specimens 50 times.

Housing Panel Retention - Test Group 7

The housings did not dislodge from the test panel, and no damage occurred to the locking mechanism.

Housing Lock Strength - Test Group 2

Mated specimens did not unmate under an axial load of 113.4 N [30 lbf].

Thermal Shock - Test Group 2

No evidence of physical damage was visible as a result of thermal shock testing.

Humidity/temperature Cycling - Test Group 2

No evidence of physical damage was visible as a result of humidity/temperature cycling.

Salt Spray Corrosion - Test Group 4

No evidence of physical damage was visible as a result of exposure to a salt spray atmosphere.

(mm

Wire Size

1.32 [16]

0.20 [24]

0.30 [22]

0.50 [20]

0.80 [18]

2.28 [14]

2

[AWG])

Figure 3

Crimp Tensile

(N [lbf] min)

133.4 [30]

200.2 [45]

222.4 [50]

62.3 [14]

62.3 [14]

35.6 [8]

110-213

4 of 7