926681-3 TE Connectivity, 926681-3 Datasheet - Page 5

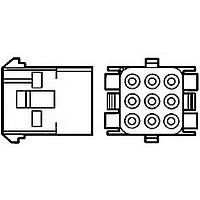

926681-3

Manufacturer Part Number

926681-3

Description

CAP, 12WAY

Manufacturer

TE Connectivity

Series

Universal Mate-N-Lokr

Datasheet

1.926647-3.pdf

(7 pages)

Specifications of 926681-3

Gender

Receptacle

No. Of Contacts

12

No. Of Rows

3

Pitch Spacing

6.35mm

Contact Gender

Socket

Connector Mounting

Free

Contact Material

Bronze

Approval Category

VDE, UL, CSA

Product Type

Connector

Product Line

Universal MATE-N-LOK

Connector Type

Housing

Mount

Free Hanging

Color

Natural

Mating Retention Type

Positive Lock

High Current

No

Current Rating (a)

19

Voltage (vac)

600

Row-to-row Spacing (mm [in])

6.35 [0.250]

Centerline (mm [in])

6.35 [0.250]

Number Of Positions

12

Mating Retention

With

Contact Diameter (mm [in])

2.13 [0.084]

Contact Type

Pin or Socket

Contact Layout

Matrix

Sealable

No

Connector Style

Receptacle

Housing Material

Polyamide - GF

Ul Flammability Rating

UL 94V-0

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

One Piece Housing

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

926681-3

Manufacturer:

TE Connectivity AMP Connectors

Quantity:

2 700

3.

3.1.

3.2.

3.3.

3.4.

3.5.

3.6.

3.7.

3.8.

Rev A

TEST METHODS

Examination of Product

Specimens were visually examined and no evidence of physical damage detrimental to product

performance was observed.

Termination Resistance, Specified Current

The potential drop of mated contacts assembled in housing was measured and the resistance

calculated.

Termination Resistance, Dry Circuit

Dry circuit termination resistance measurements were made using a 4 terminal measuring technique.

The test current was maintained at 100 milliamperes maximum with a 50 millivolt maximum open circuit

voltage.

Dielectric Withstanding Voltage

A test potential of 5 kVAC was applied between the adjacent contacts of mated specimens. This

potential was applied for 1 minute and then returned to zero.

Insulation Resistance

Insulation resistance was measured between adjacent contacts of mated specimens. A test voltage of

500 volts DC was applied for 2 minutes before the resistance was measured.

Temperature Rise vs Current

Temperature rise curves were produced by measuring individual contact temperatures at different

current levels. These measurements were plotted to produce a temperature rise vs current curve.

Thermocouples were attached to individual contacts to measure their temperatures. The ambient

temperature was then subtracted from this measured temperature to find the temperature rise. When

the temperature rise of consecutive readings did not differ by more than 1

measurement was recorded.

Vibration

Mated specimens were subjected to sinusoidal vibration, having a simple harmonic motion with an

amplitude of 1.5 mm [0.06 in], double amplitude. The vibration frequency was varied uniformly between

the limits of 10 and 55 Hz and returned to 10 Hz in 1 minute. This cycle was performed 120 times in

each of 3 mutually perpendicular planes for a total vibration time of 6 hours. Specimens were monitored

for discontinuities of 10 microseconds or greater using a current of 100 milliamperes DC.

Physical Shock

Mated specimens were subjected to a physical shock test having a sawtooth waveform of 50 gravity

units (g peak) and a duration of 10 milliseconds. Three shocks in each direction were applied along the

3 mutually perpendicular planes for a total of 18 shocks. Specimens were monitored for discontinuities

of 10 microseconds or greater using a current of 100 milliamperes DC.

/

C , the temperature

110-213

5 of 7