5-640861-1 TE Connectivity, 5-640861-1 Datasheet

5-640861-1

Specifications of 5-640861-1

Related parts for 5-640861-1

5-640861-1 Summary of contents

Page 1

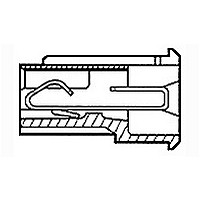

... Connector, MTA 156, Card Edge 1. SCOPE 1.1. Content This specification covers the performance requirements for the TE Connectivity (TE) MTA 156 card edge connector system. This system provides a reliable interconnection between wires and printed circuit boards. 1.2. Qualification When tests are performed on the subject product line, procedures specified in Figure 1 shall be used. ...

Page 2

... Apply force parallel to axis of wire. TE Spec 109-16. Determine slot tensile at a rate of 1 inch per minute. Apply force perpendicular to axis of wire on samples without cover. TE Spec 109-27. Manually mate and unmate connector assemblies with printed circuit board for 25 cycles. Mount printed circuit board in fixture ...

Page 3

... TE Spec 109-30. Pull on contact using special cut- away housing. TE Spec 109-42. Measure force necessary to mate connector assembly with printed circuit board a distance of .125 inch from point of initial contact. Calculate force per contact. TE Spec 109-42. Measure force necessary to unmate connector assembly and printed circuit board ...

Page 4

... Sheets and shall be selected at random from current production. Test group 1 shall consist of 1 connector of each size, all representative of the entire lot being tested. Test groups 2 through 4 shall consist of 2 connector assemblies per group per wire size. Test group 5 shall consist of 15 contacts chosen randomly from 5 connector assemblies. Test group 6 shall consist of 4 connector assemblies per wire size. Each wire size shall consist of solid, stranded and prefused or overcoated wire ...

Page 5

... A 1 foot minimum length of continuous lead for heat dissipation. NOTE 2. Termination resistance equals millivolts divided by test current less resistance of 3 inches of wire and resistance of .90 inch of printed circuit board pad. Temperature and Resistance Measurement Points Rev D Figure 3 108-1058 ...

Page 6

... Rev D Figure 4 Terminal Temperature vs Current/Circuit 24 Circuit Assembly 108-1058 ...

Page 7

... Dimensions are in inches. NOTE 2. Unless otherwise specified, tolerance is ± .005. 3. Number of contacts shall be the same as on the corresponding printed wiring connector. 4. Printed circuit test board, type G10 or equivalent, shall be 3 ounce copper with .000600 minimum tin electrodeposited plating overall thickness .062 +.008/-.007. ...