5-640861-1 TE Connectivity, 5-640861-1 Datasheet - Page 2

5-640861-1

Manufacturer Part Number

5-640861-1

Description

21P MTA156 EDGE CONN ASSY LF

Manufacturer

TE Connectivity

Specifications of 5-640861-1

Connector Type

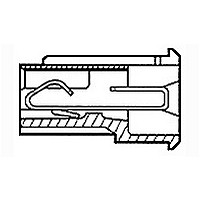

Connector Assembly

Connector Design

Closed End

Product Line

MTA-156

Termination Method To Wire/cable

IDC Standard

Wire Size (mm² [awg])

0.3-0.4² [22]

Pcb Mounting Orientation

Horizontal

Pcb Mount Retention

Without

Mating Connector Lock

Without

Four Points Of Contact

Without

Shrouded

No

Mounting Ears

Without

Panel Mount Retention

Without

Current Rating (a)

7

Solder Tail Contact Plating

Bright Tin

Number Of Positions

21

Centerline (mm [in])

3.96 [0.156]

Cable Exit Angle

90°

Contact Plating, Mating Area, Material

Tin

Contact Base Material

Copper Alloy

Connector Style

Card Edge

Housing Color

Red

Mating Alignment

Without

Ul Flammability Rating

UL 94V-0

Housing Material

Polyester

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Applies To

Wire/Cable

Application Use

Wire-to-Board

3.5.

Rev D

Examination of product.

Termination resistance, dry circuit.

Termination resistance, specified

current.

Insulation resistance.

Dielectric withstanding voltage.

Temperature rise vs current.

Tensile, straight.

Tensile, perpendicular.

Durability.

Test Requirements and Procedures Summary

Test Description

Meets requirements of product

drawing and Application

Specification 114-1020.

4.0 milliohms maximum initial.

5000 megohms minimum initial.

1000 megohms minimum final.

1.25 kvac at sea level.

1 minute hold with no breakdown or

flashover.

See Figure 4.

See Note.

(AWG) (amperes)

Wire

Size

26

24

22

20

18

Wire Size

Wire Size

(AWG)

(AWG)

Figure 1 (continued)

26

24

22

20

18

26

24

22

20

18

Specified

MECHANICAL

ELECTRICAL

Current

Requirement

1.0

1.0

1.5

2.0

3.0

(Lb minimum)

(Lb minimum)

Slot Tensile

Slot Tensile

Maximum

12.0

17.0

30.0

Milliohms

5.0

8.0

1.3

1.3

3.4

4.0

4.6

(initial)

5.0

5.0

4.0

4.0

4.0

Visual, dimensional and functional

per applicable inspection plan.

TE Spec 109-6-1, Condition A.

Subject mated connectors

assembled in housing to 50 mv

open circuit at 100 ma maximum.

See Figure 3.

TE Spec 109-25.

Measure potential drop of mated

contacts assembled in housing.

Calculate resistance.

See Figure 3.

TE Spec 109-28-4.

Test between adjacent contacts of

unmated connector assemblies.

TE Spec 109-29-1.

Test between adjacent contacts of

unmated connector assemblies.

TE Spec 109-45-2.

Temperature rise at rated current.

TE Spec 109-16.

Determine slot tensile at a rate of 1

inch per minute. Apply force parallel

to axis of wire.

TE Spec 109-16.

Determine slot tensile at a rate of 1

inch per minute. Apply force

perpendicular to axis of wire on

samples without cover.

TE Spec 109-27.

Manually mate and unmate

connector assemblies with printed

circuit board for 25 cycles. Mount

printed circuit board in fixture.

Procedure

108-1058

2 of 7