776532-2 TE Connectivity, 776532-2 Datasheet - Page 2

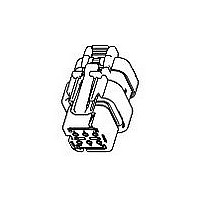

776532-2

Manufacturer Part Number

776532-2

Description

AS 16, 8P PLUG ASSY, RD, KEY 2

Manufacturer

TE Connectivity

Specifications of 776532-2

Product Line

AMPSEAL 16

Product Type

Connector

Connector Type

Housing

Mount Angle

Straight

Mount

Free Hanging

Mating Retention Type

Latching

Seal Type

Peripheral and Wire Seals

Centerline (mm [in])

4.50 [0.177]

Number Of Rows

2

Row-to-row Spacing (mm [in])

5.30 [0.209]

Number Of Positions

8

Mating Retention

With

Fluid Type

Water

Contact Type

Socket

Contact Layout

In-Line

Connector Style

Plug

Mating Alignment

With

Housing Color

Gray

Mating Alignment Type

Color Coded, Keyed, Terminal Position Assurance

Housing Material

Thermoplastic - GF

Environmental Protection

With

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Fluid Resistance

Immersion

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

776532-2

Manufacturer:

TE Connectivity AMP Connectors

Quantity:

183

3.

3.1.

3.2.

3.3.

3.4.

3.5.

Rev B

Visual inspection.

REQUIREM ENTS

Design and Construction

Product shall be of the design, construction and physical dim ensions specified on the applicable product

drawing.

Materials

Materials used in the construction of this product shall be as specified on the applicable product

drawing.

Ratings

!

!

!

!

!

Perform ance and Test Description

Product is designed to m eet the electrical, m echanical and environm ental perform ance requirem ents

specified in Figure 2. Unless otherwise specified, all tests shall be perform ed at am bient environm ental

conditions.

Test Requirem ents and Procedures Sum m ary

Test Description

Voltage: 250 volts DC

Current: See Figure 1 (all readings in am peres)

Tem perature: -40 to 125°C

Ingress Protection (IP) level: IP67

Flam m ability: UL94HB

Single Circuit Energized

All Circuits Energized (12 position connector)

Connector Loading

Meets requirem ents of product

drawing.

Figure 2 (continued)

Requirem ent

Figure 1

16.0

9.0

14

W ire Size (AW G)

Visual inspection of product before

(and after) unm ating connectors for

conditions such as torn seals,

cracked plastic, evidence of fluid or

dust ingress in sealed connector

system s, arcing, charing, m elting,

or anything that affects the

perform ance or serviceability of the

product as deem ed by qualified

Engineer.

10.0

6.0

18

5.0

7.0

Procedure

20

108-2184

2 of 6