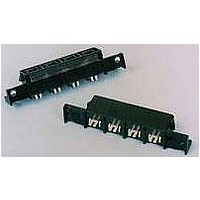

556881-7 TE Connectivity, 556881-7 Datasheet

556881-7

Specifications of 556881-7

Related parts for 556881-7

556881-7 Summary of contents

Page 1

... Receptacle: Polyphthalmide, UL 94V-0 • Plug: Polycarbonate, UL 94V-0 ©2011 Tyco Electronics Corporation, | Indicates change a TE Connectivity Ltd. Company *Trademark All Rights Reserved TE logo is a trademark. For latest revision, visit our website at www.te.com/documents. For Regional Customer Service, visit our website at www.te.com Other products, logos, and company names might be trademarks of their respective owners. ...

Page 2

Ratings ! Voltage: 600 volts alternating current (rms) ! Current: See Figure 4 for applicable current carrying capability ! Temperature 105° C 3.4. Performance and Test Description Product is designed to meet the electrical, mechanical and environmental ...

Page 3

Test Description Durability. Mating force. Unmating force. Thermal shock. Humidity-temperature cycling. Temperature life. Shall meet visual requirements, show no physical damage, and meet requirements of additional NOTE tests as specified in the Product Qualification and Requalification Test Sequence shown in ...

Page 4

Product Qualification and Requalification Test Sequence Examination of product Termination resistance Insulation resistance Dielectric withstanding voltage Temperature rise vs current Vibration Mechanical shock Durability Mating force Unmating force Thermal shock Humidity-temperature cycling Temperature life (a) See paragraph 4.1.A. NOTE ...

Page 5

Acceptance Acceptance is based on verification that the product meets the requirements of Figure 1. Failures attributed to equipment, test setup or operator deficiencies shall not disqualify the product. When product failure occurs, corrective action shall be taken and ...

Page 6

Rated Current vs Ambient Temperature Rating for Single Circuit 1 .062 inch thick printed circuit board, 2 ounce copper trace, double sided, .360 inch wide trace. NOTE Percent Connector Loading Single Contact To determine acceptable current carrying capacity for the ...

Page 7

Vibration & Mechanical Shock Mounting Fixture Rev A Figure 5 Temperature Rise Measurement Points Figure 6 (Fixture 92-660368-000-1 through -004) 108-1349 ...