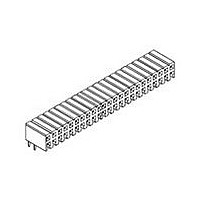

4-1734531-8 TE Connectivity, 4-1734531-8 Datasheet

4-1734531-8

Specifications of 4-1734531-8

Related parts for 4-1734531-8

4-1734531-8 Summary of contents

Page 1

... TYCO SPECIFICATIONS A. 109-1: General Requirements for Test Specifications B. 109 series: Test Specification as indicated in figure 2 (Comply with MIL-STD-202) C. Corporate Bulletin 401-76: Cross-reference between Tyco test Specifications and Military or Commercial Documents. D. 501-57197: Test Report. 3. REQUIREMENTS 3.1. DESIGN AND CONSTRUCTION Product shall be of the design, construction and physical dimensions specified on the applicable product drawing ...

Page 2

... RATINGS A. Voltage: 250 VAC rms. B. Current Max C. Operating Temperature: -40° 105° C 3.4. PERFOMANCE AND TEST DESCRIPTION The product is designed to meet the electrical, mechanical and environmental performance requirements specified in Table 2. All tests are performed at ambient environmental conditions per AMP Specification 109-1 unless otherwise specified ...

Page 3

... MIL-STD-202, Method201, Condition A Subject mated connector assemblies to temperature life at 85° C±2° C for 96 hours. Subject mated connectors to steady state humidity at 40° C±2° C and 90-95% R.H for 96 hrs. Subject mated connector assemblies on 5 cycle –55 ° C and +80° C for 30 minutes each duration at temperature extremes ...

Page 4

... Thermal Shock 3.5.4.5 Resistance to Soldering Heat 3.5.4.6 Durability 3.5.4.7 Salt Spray 3.5.4.8 Resistance to Soldering Heat (a) Numbers indicate sequence in which tests are performed. (b) Discontinuities shall not be measured. Rev B Test Group Test Sequence (a) 1,5 1,9 1,6 1,5 1,5 1,4 2,4 8 2,4 2,4 2,5 3 2,5 3 4,7 3 Figure 2 108-57197 1,3 1,3 1,5 1,3 2 ...

Page 5

FIGURE 3. CONTACT RESISTANCE & RESISTANCE TO FLOW SOLDER HEAT Rev B 108-57197 ...