4-1734531-8 TE Connectivity, 4-1734531-8 Datasheet - Page 2

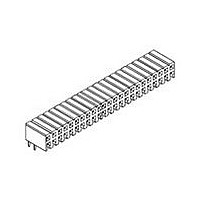

4-1734531-8

Manufacturer Part Number

4-1734531-8

Description

Manufacturer

TE Connectivity

Specifications of 4-1734531-8

Product Type

Connector

Connector Type

Connector Assembly

Pcb Mount Style

Through Hole

Shrouded

No

Pcb Mount Retention

Without

Pcb Mounting Orientation

Right Angle

Keyed

No

Holddown Feature

Without

Post Size (mm [in])

0.50 [.020]

Voltage (vac)

200

Contact - Rated Current (a)

1

Insulation Resistance (m?)

1,000

Termination Post Length (mm [in])

3.00 [0.118]

Solder Tail Contact Plating

Tin over Nickel

Centerline (mm [in])

2.00 [0.079]

Number Of Positions

48

Selectively Loaded

No

Post Number(s) Omitted

None

Centerline, Matrix (mm [in])

2.00 x 2.00 [.079 x .079]

Mating Pin-to-pcb Dimension (mm [in])

1.50 [0.059]

Mount Type

Printed Circuit Board

Number Of Rows

Dual

Cover

Without

Contact Plating, Mating Area, Material

Gold (10)

Contact Base Material

Phosphor Bronze

Connector Style

Receptacle

Housing Material

Thermoplastic - GF

Dielectric Strength (vac)

650

Ul Flammability Rating

UL 94V-0

Housing Color

Black

Housing Entry Style

Closed Top

Stack Height (mm [in])

4.85 [0.191]

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Wave solder capable to 240°C, Wave solder capable to 260°C, Wave solder capable to 265°C

Rohs/elv Compliance History

Always was RoHS compliant

Approved Standards

UL E28476, CSA LR7189

Temperature Range (°c)

-40 – +105

Pcb Thickness, Recommended (mm [in])

1.57 [0.062]

Packaging Method

Tube

3.5.2.1

3.5.2.2

3.5.2.3

3.5.3.1

3.5.3.2

3.5.3.3

3.5.3.4

Rev

3.5.1

NO.

3.3. RATINGS

3.4. PERFOMANCE AND TEST DESCRIPTION

3.5. TEST REQUIREMENTS AND PROCEDURES SUMMARY

B

A. Voltage: 250 VAC rms.

B. Current: 1 A Max

C. Operating Temperature: -40° C to + 105° C

Examination of

Product

Termination

Resistance

Insulation

Resistance

Dielectric Strength

Individual Pin

Insertion/ Extraction

Force

Receptacle Contact

Retention Force

Post Retention

Force

Solder ability

TEST ITEMS

The product is designed to meet the electrical, mechanical and environmental

performance requirements specified in Table 2. All tests are performed at

ambient environmental conditions per AMP Specification 109-1 unless otherwise

specified.

Meets requirements of product

drawing. No physical damage.

1000M ohms min. (Initial)

1000M ohms min (Final)

Connector must withstand test

potential of 650VAC for 1 min.

Current leakage limit to 5.0mA

max.

250 gf min. per contact

0.5 kgf min. per contact

The inspected area of each lead

must have 95% solder coverage

minimum.

Insertion Force

200 gf max

Initial

Final

MECHANICAL REQUIREMENTS

ELECTRICAL REQUIREMENTS

REQUIREMENTS

20m ohms max.

30m ohms max.

Extraction

10gf min

Force

Visual inspection.

Subject mated contacts assembled in

housing to closed circuit current of 50mA

max at open circuit voltage of 50mV max.

(See Fig. 1)

Measure by applying test potential between

adjacent contacts, and between the

contacts and ground in the mated connector

assembly.

MIL-STD-202, Method 302, Condition B

Measure by applying test potential between

adjacent contacts, and between the

contacts and ground in the mated connector

assembly.

MIL-STD-202, Method 301

Subject terminated contact and pin to mate

and unmate to measure the force required

to insert and extract by operating at a rate of

100mm a minute. (See Fig. 2)

Apply axial load to terminated contact at a

rate of 25mm a minute.

Apply axial pull-off load to post contact

mounted on housing and measure the force

required to dislodge post from housing.

Steam Aging Preconditioning:

(1) Tin、Tin-Cu Coating:

93+3/-5℃、100% HR、8hrs.

<J-STD-002 category 3 aging>

(2) Other Coating:

93+3/-5℃、100% HR、1hrs.

<J-STD-002 category 2 aging>

Solder pot temperature: 245±5℃, 5sec

PROCEDURES

108-57197

2 of 5