640432-7 TE Connectivity, 640432-7 Datasheet - Page 5

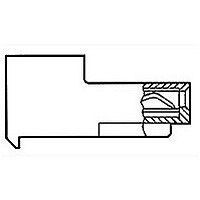

640432-7

Manufacturer Part Number

640432-7

Description

Manufacturer

TE Connectivity

Specifications of 640432-7

Connector Type

Connector Assembly

Connector Design

Closed End

Product Line

MTA-156

Termination Method To Wire/cable

IDC Standard

Wire Size (mm² [awg])

0.5-0.6² [20]

Mating Connector Lock

Without

Four Points Of Contact

Without

Shrouded

No

Mounting Ears

Without

Panel Mount Retention

Without

Current Rating (a)

7

Voltage Rating (vac)

600

Solder Tail Contact Plating

Tin-Lead

Number Of Positions

7

Centerline (mm [in])

3.96 [0.156]

Narrow

No

Post Number(s) Omitted

None

Cable Exit Angle

90°

Contact Type

Socket

Contact Plating, Mating Area, Material

Tin-Lead

Contact Base Material

Copper Alloy

Connector Style

Receptacle

Housing Color

Yellow

Mating Alignment

Without

Ul Flammability Rating

UL 94V-2

Housing Material

Nylon

Rohs/elv Compliance

Not ELV/RoHS compliant

Lead Free Solder Processes

Not relevant for lead free process

Applies To

Wire/Cable

Application Use

Wire-to-Board

4.

4.1.

4.2.

4.3.

Rev F

QUALITY ASSURANCE PROVISIONS

Qualification Testing

A.

B.

Acceptance

Acceptance is based on verification that the product meets the requirements of Figure 1. Failures

attributed to equipment, test setup or operator deficiencies shall not disqualify the product. If product

failure occurs, corrective action shall be taken and samples resubmitted for qualification. Testing to

confirm corrective action is required before resubmittal.

Quality Conformance Inspection

The applicable quality inspection plan shall specify the sampling acceptable quality level to be used.

Dimensional and functional requirements shall be in accordance with the applicable product drawing

and this specification.

Sample Selection

Connector housings and contacts shall be prepared in accordance with applicable Instruction

Sheets and shall be selected at random from current production. Test group 1 shall consist of 1

connector of each size, all representative of the entire lot being tested. Test groups 2 through 6

shall consist of 2 connector assemblies per group per wire size. Test group 7 shall consist of 15

contacts chosen randomly from 5 connector assemblies. Test group 8 shall consist of 4 connector

assemblies per wire size. Each wire size shall consist of solid, stranded and prefused or

overcoated wire; UL style 1007 or 1061 tin plated. Stranded wire shall consist of 7 strands. All

wires shall be applied in accordance with Application Specification 114-1020. Complete

qualification of the product line can be accomplished by sampling the product using all variations of

wire size, type and connector design. Partial qualification can be accomplished by using only one

variation of wire size, type or connector design.

Test Sequence

Qualification inspection shall be verified by testing samples as specified in Figure 2.

108-1065

5 of 7