sky73112-11 Skyworks Solutions, Inc., sky73112-11 Datasheet - Page 3

sky73112-11

Manufacturer Part Number

sky73112-11

Description

Sky73112-11 750-850 Mhz High Performance Vco/synthesizer With Integrated Switch

Manufacturer

Skyworks Solutions, Inc.

Datasheet

1.SKY73112-11.pdf

(22 pages)

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

SKY73112-11

Manufacturer:

Skyworks

Quantity:

1 400

Part Number:

SKY73112-11

Manufacturer:

SKYWORKS/思佳讯

Quantity:

20 000

Technical Description

The SKY73112-11 is a fractional-N frequency synthesizer using a

provides low in-band noise by having a low division and fast

frequency settling time. The device also provides programmable,

arbitrary fine frequency resolution. This compensates the

frequency synthesizer for crystal frequency drift.

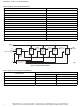

Serial I/O Control Interface

The SKY73112-11 is programmed through a three-wire serial bus

control interface using four 26-bit words. The three-wire interface

consists of three signals: CLK (pin 17), LE (pin 19), and the bit

serial data line DATA (pin 18). The convention is to load data from

the most significant bit to the least significant bit (MSB to LSB). A

serial data input timing diagram is shown in Figure 3. Preset

timing parameter values are provided in Table 2.

Although the SKY73112-11 uses a 5 V DC supply, the internal

voltage regulator has a 3.3 V output for the PLL. Therefore, the

input DC voltage for the serial interface (CLK, DATA, and LE

signals) should be set to 3.3 V or lower.

Figure 4 depicts the serial bus, which consists of one 26-bit load

register and four separate 24-bit registers. Data is initially clocked

into the load register starting with the MSB and ending with the

LSB. The LE signal is used to gate the clock to the load register,

requiring the LE signal to be brought low before the data load.

Data is shifted on the rising edge of CLK.

The two final LSBs are decoded to determine which holding

register should latch the data. The falling edge of LE latches the

data into the appropriate holding register. This programming

sequence must be repeated to fill all four holding registers.

The specific hold register addresses are determined by the wd_0

and wd_1 parameters in the load register. These are the two

LSBs (bits [1:0]) as shown in Figure 4. Table 3 lists the four hold

registers and their respective addresses as determined in the load

register.

The contents of each word in the load register are used to

program the four hold registers described in Tables 4 through 7.

modulation technique. The fractional-N implementation

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

DATA

200736B • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • November 30, 2009

CLK

LE

Figure 3. SKY73112-11 Serial Data Input Timing Diagram (MSB First)

t

DSU

t

DHD

The dpll_ctrl parameter (bits [19:2] of Word 1) programs the

Digital Phase Locked Loop (DPLL) block. Each of the 18 bits that

comprise the dpll_ctrl parameter map directly to the signal ports

on the DPLL block as shown in Table 8 (except for the

dpll_flag_override and dpll_flag_value parameters).

Loading new data into a holding register not associated with the

synthesizer frequency programming does not reset or change the

synthesizer. The synthesizer should not lose lock before, during,

or after a new serial word load that does not change the

programmed frequency.

VCO Auto-Tuning Loop

A VCO auto-tuning loop provides the proper 7-bit coarse tuning

setting for the VCO switch capacitors in the VCO output. This sets

the oscillation frequency as close to target as possible before

starting fine analog tuning.

When VCO auto-tuning is enabled, the PLL performs a seven-step

successive approximation process to digitally tune the VCO close

to the final programmed frequency. Once that is complete, analog

tuning is switched in to lock the VCO to the programmed

frequency.

The auto-tuning loop is designed to compensate process variation

so that the VCO fine tuning range can be reduced to cover

temperature variation only. It significantly reduces VCO gain (Kv)

which reduces VCO phase noise.

There are two conditions that enable the VCO auto-tuning

function: a Power-On-Reset (POR) and a change in frequency. The

difference in the program flow under each of these conditions is

illustrated in Figure 5. Under either condition, dpll_en (bit [20] of

Word 1) should first be cleared so that a rising edge pulse can be

generated. Following this pulse, set dpll_en to enable VCO auto-

tuning.

A POR timing diagram is shown in Figure 6. VCO auto-tuning

details in the frequency and time domains are shown in Figure 7.

t

CKH

t

CKL

DATA SHEET • SKY73112-11 VCO/SYNTHESIZER

t

CLE

t

LEW

t

LEC

S1053

3